Aerodynamic optimisation of a side mirror for the purpose of lowering noise emissions

Motivation

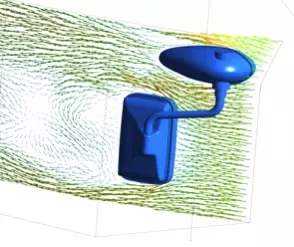

At high speeds, relatively high noise emissions that are uncomfortable for the train driver are produced in the train cab due to the air flow dynamics. The goal of the present project was to minimise noise emissions through the aerodynamic adjustment of the side mirror geometry. A numeric air flow simulation was used to replicate the air flow dynamics of the train's outer contours, and to thereby determine the relevant source of the noise pollution.

Implementation and Results

At first, an airflow simulation reflecting the current condition was created. Thanks to this, it was possible to determine which optimisation measures promised the highest success. Aerodynamic enhancements were designed based on these results. These modifications were calculated through an additional simulation, to quantify the enhancements. This method facilitated the new design of the rear-view mirror.

Using Rapid Prototyping, a prototype of the newly designed side mirror was produced, to validate the simulation results using noise measurement in the train cab. The measurements confirmed the results of the simulation and reflected significantly lowered noise emissions achieved by using the new rear-view mirror section.

At one glance

Involved Institutes and centers:

Project partner:

Co-financing:

- Innosuisse (former KTI)

Project status: completed