Ceramic filters against coronaviruses

The Institute of Materials and Process Engineering (IMPE) and the Institute of Computational Physics (ICP) develop ceramic filters for masks, air purifiers and air conditioning systems.

In an internally funded project by the School of Engineering, an interdisciplinary team from the IMPE Institute of Materials and Process Engineering and ICP Institute of Computational Physics is investigating the benefits of custom-made ceramic filters for aerosol filtration and virus removal. Ceramic filters have some significant advantages over standard filters, which are made from polymer fibre fleeces. The microstructure and geometry of the ceramic pore channels can be adjusted over a wide range as desired. Ceramics can be easily sterilised by simple heating, making multiple use and internal regeneration of a filter possible. Ceramics are virtually artificial stone and therefore completely uncritical in terms of environmental impact and recycling, while the massive use and uncontrolled waste of polymer microfibres represents a significant new source of microplastics.

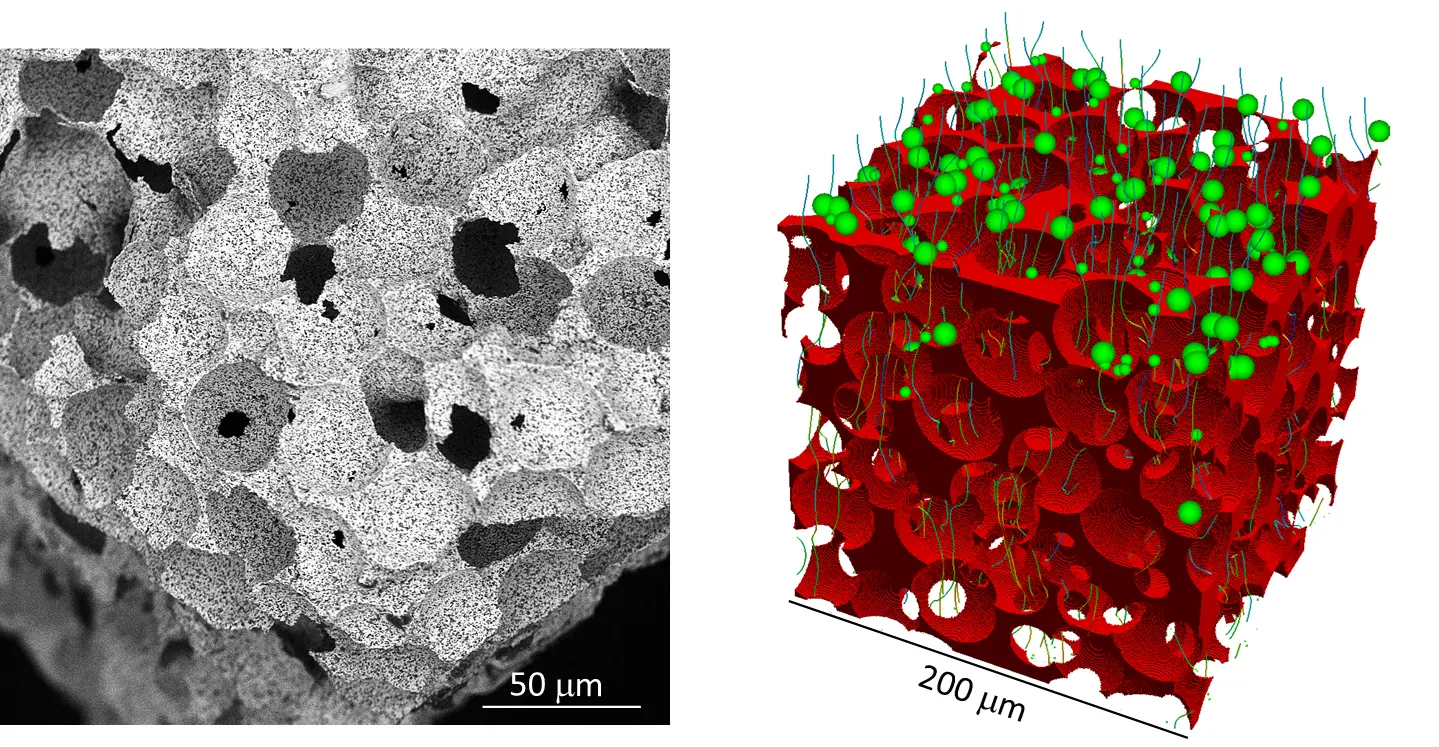

The ZHAW team led by Dirk Penner (IMPE, Laboratory for Ceramic Materials) and Lorenz Holzer (ICP, Microstructure Analysis and Property Prediction Group) is using state-of-the-art modelling tools to create virtual models of the porous ceramics produced in the laboratory and to investigate the pressure loss, permeability and filtration performance of the materials. The results can then be compared with real measurements on individual ceramic samples. Once the model has been validated, laws can be derived on the computer from hundreds of artificially created structures, which in turn serve ceramic researchers as a design basis for their development. This reduces the number of laboratory tests required to develop optimised filter materials that already take into account the standard requirements for the filter materials as a set framework.

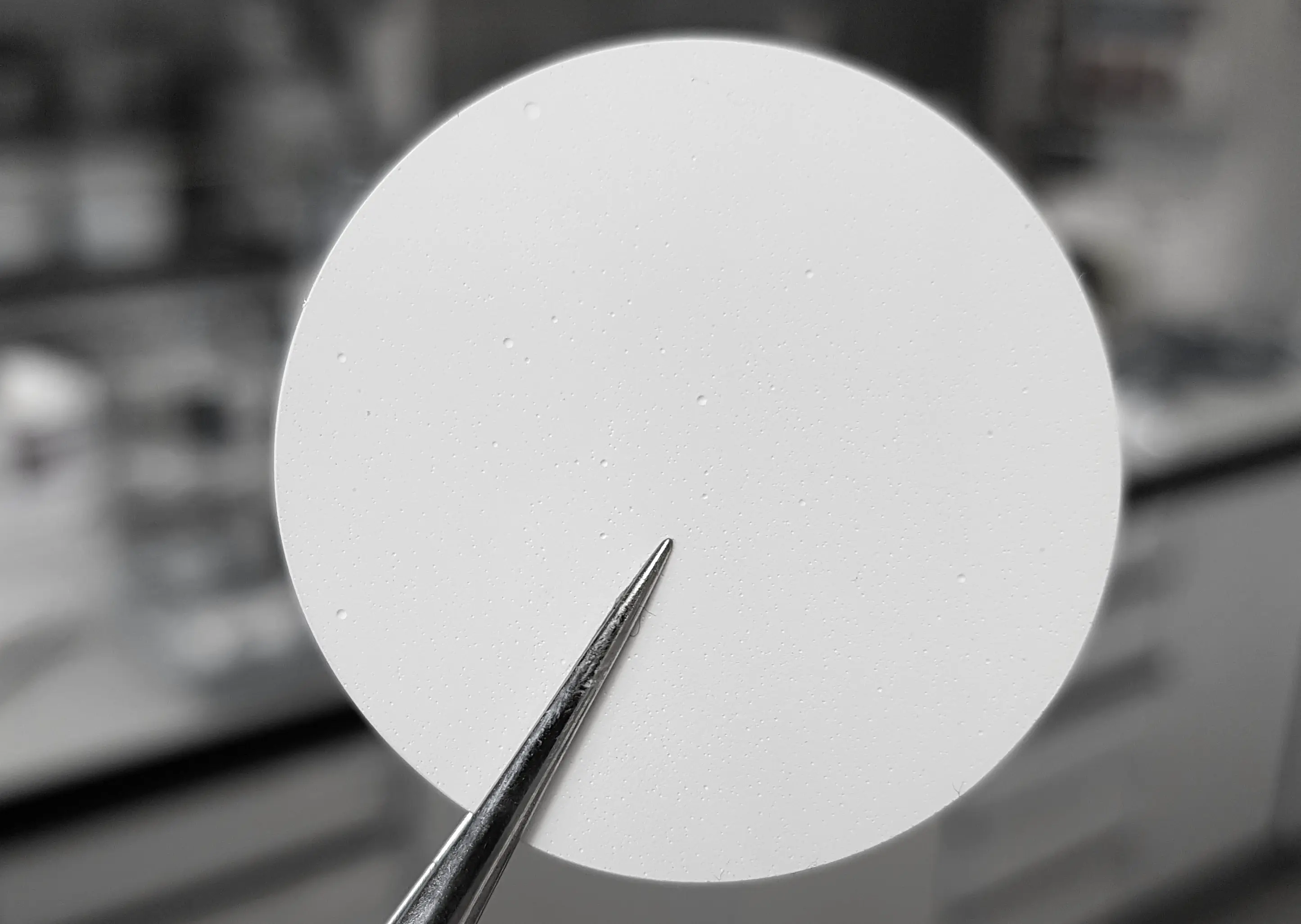

In the near future, on the one hand, new highly efficient ceramic filters for use in face masks are to be presented and, on the other hand, self-regenerating filters are to be produced and tested as demonstrators for technical applications by implementing a heating layer within the ceramic filter. Further functionalisations such as impregnation with microbially active coatings are also possible. The team is open to collaborations with academic and industrial research partners to bring new and innovative products to market in a short time.