Wireless sensors for monitoring and control of extrusion processes

In order to be able to monitor the technical process of plastics extrusion in real time and control it within the framework of target specifications, the process engineer needs process data that is as accurate and up-to-date as possible. Radio-based technologies make it possible to transmit important measured variables such as pressure values and temperatures from the moving parts of a system (roll) online for real-time evaluation and thus significantly improve the possibilities of process control.

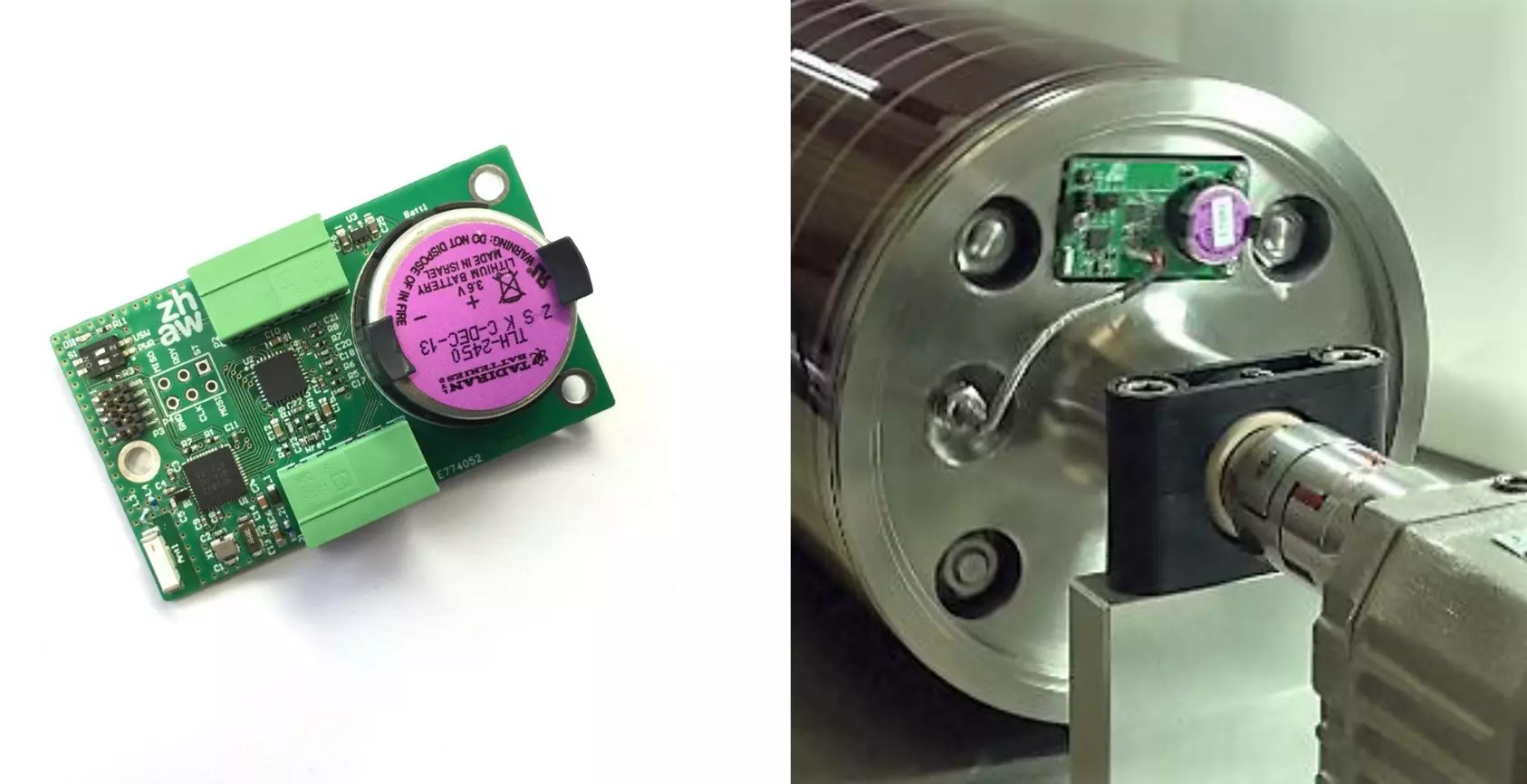

Derichs has commissioned the Institute of Signal Processing and Wireless Communications (ISC) to develop an IoT-capable, high-precision, autonomous and wireless sensor that can be integrated into the rolls of extrusion lines.

The design had to be power-saving, accurate to tenths of a degree Celsius and bar, and IoT-capable. Thermal measures allow mounting even on rollers with up to 200 °C. Since the sensors measure directly in the roll, the measured values are transmitted from the rotating roll via Bluetooth 4.0. The module can broadcast the measured values periodically or log measured values over defined periods of time on the module and retrieve them afterwards as a whole data file. A connection to tablets and gateways to cloud or PLC control is easily possible. This has opened the door to real Industry 4.0 solutions for this industry.

The following goals have been achieved with the first product ED1:

- measures reliably input & output temperature and pressure

- enables faster, more effective controlling of the heating & cooling process and thus optimization of film or plate

- saves energy through more accurate control: just 1°C less temperature in the roll saves 6% energy

- extends the lifetime of your roll by precise monitoring of the roll function.

At the International Converting Exhibition ICE-2017, the ED1 of Derichs GmbH received the ICE Europe Award in the Industry 4.0 category. In Munich, more than 420 exhibitors from 26 countries displayed products for the converting of paper, film and foils on around 11,000m².

Technical data ED1

- Measuring range: 0° - 100° (optionally up to 200°)

- High accuracy: < ± 0.4°

- Update Time: typically 5 s

- Battery life: typically 2 years

- Radio range: typically 20 m

- Sensors: PT1000 1/3 DIN B

- Size: 70 mm x 40 mm

- Lightweight: 25 g

- Retrofittable into existing rollers

- Bluetooth 4.0 interface