Alpine model photovoltaic system

To estimate yields and optimize alpine solar installations, the Renewable Energies research group is carrying out measurements on a model photovoltaic system at Totalp above Davos to determine yields under variable parameters.

Background and Objective

Photovoltaics in Alpine regions make an important contribution to the accelerated expansion of electricity production in Switzerland. Thanks to generally high solar radiation, little high fog, reflections from the snow surface and low temperatures, a lot of electricity can be generated in the mountains even in winter.

About three to four times as much winter electricity is generated per unit of area in the Alps than in the lowlands, which makes such installations particularly attractive from an economic point of view. However, due to snow reflections, the use of bifacial modules, and the installation on slopes, current simulation software is not suitable for estimating yields and optimizing alpine solar installations.

In order to validate the relevant software, data from real installations of sufficient quality and parameter diversity is required. Since such data does not exist, or only to a very limited extent, it is necessary to construct alpine test facilities.

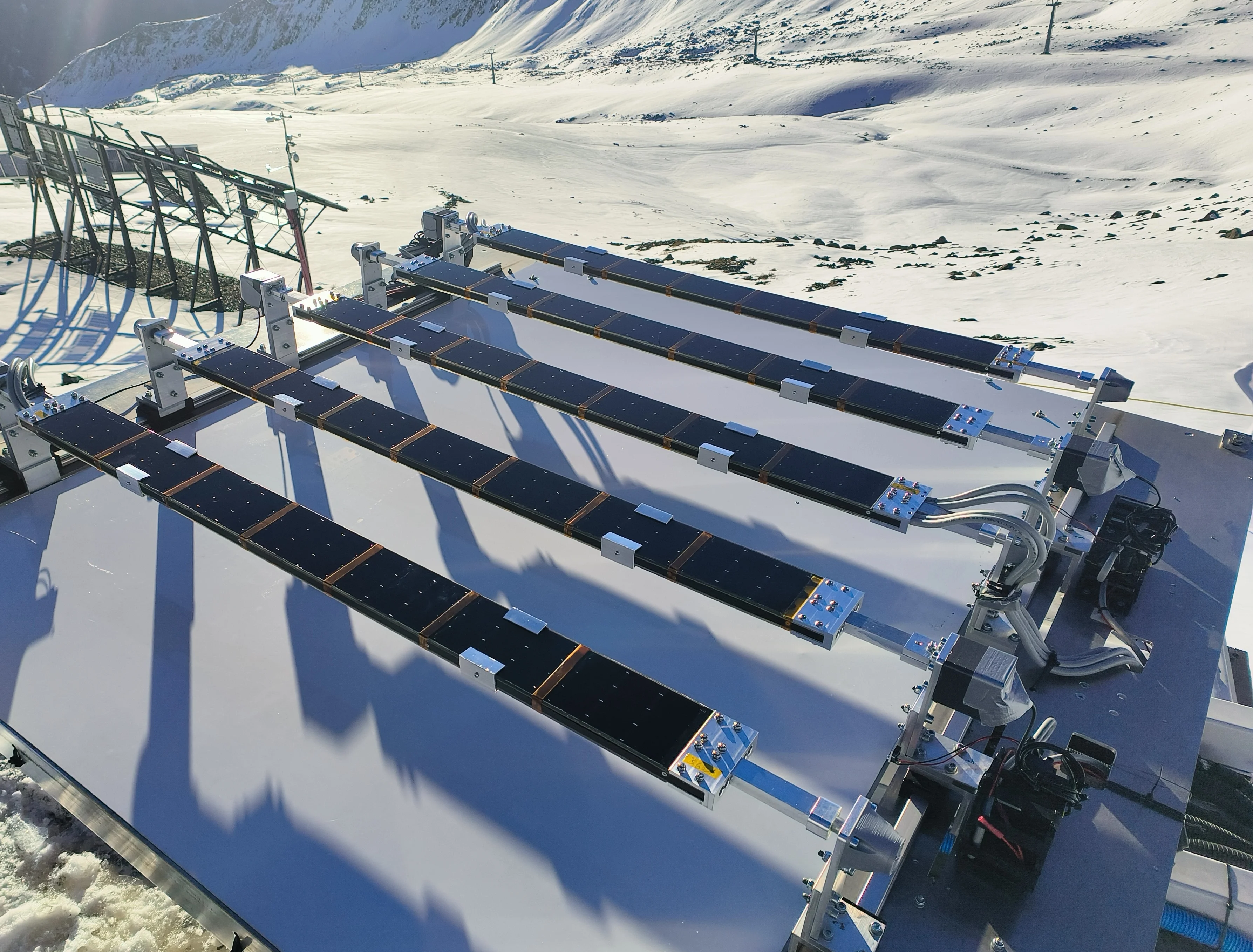

The first mini PV test facility, which was operated during the two winters of 2023/24 and 2024/25, has provided us with initial measurement data. Since the end of September 2025, the second, further developed generation of the plant has been measuring the winter electricity that can be produced in alpine regions for a wide variety of configurations, and we will therefore be able to analyze measurement data from this model plant at the end of winter 2025/26.

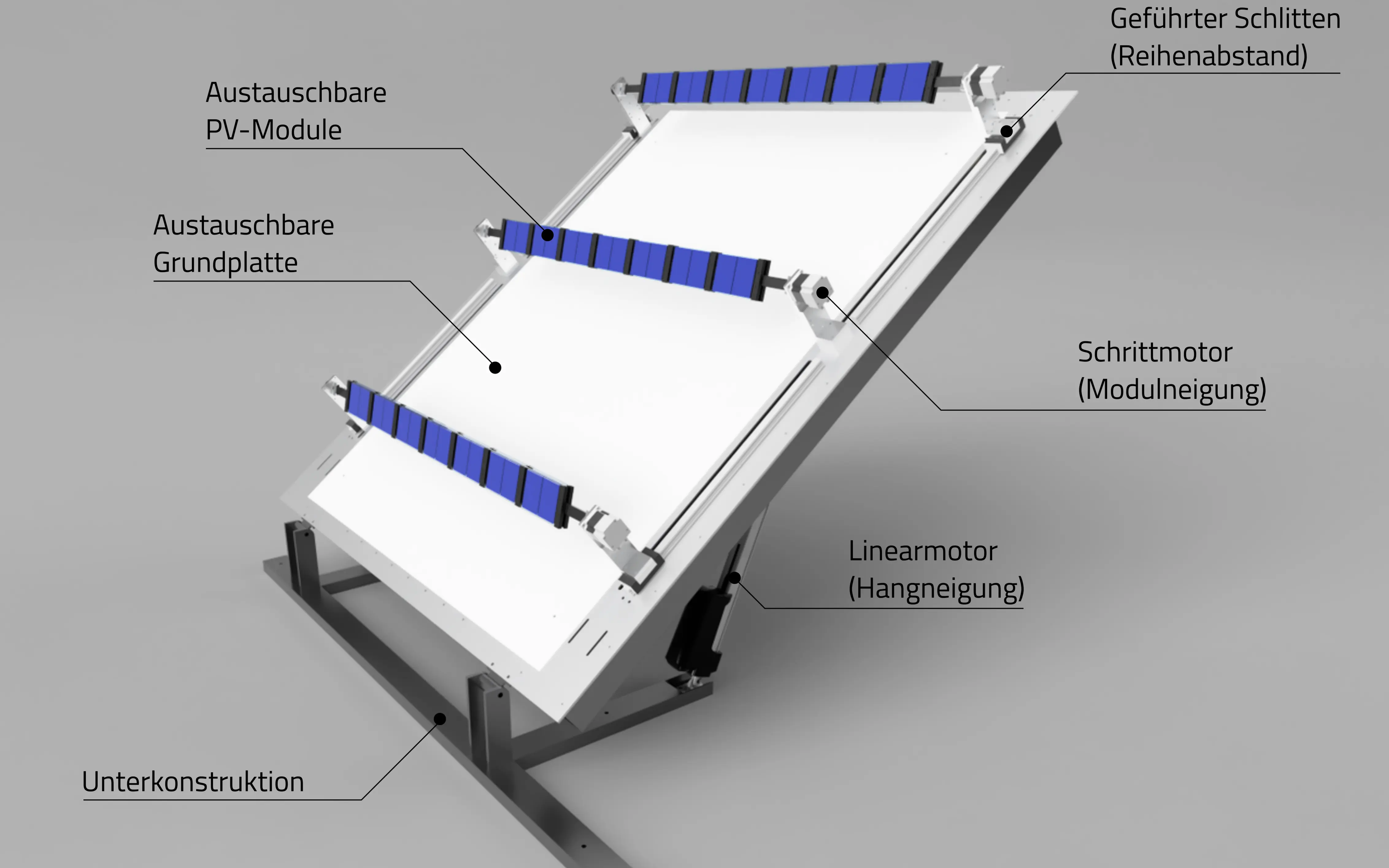

The model photovoltaic plant presented here is designed to be highly flexible in its application: it can dynamically change the row spacing, module inclinations, and slope inclination across a wide range, and the second generation of the plant can also dynamically change the slope orientation. At the same time, various external influences, such as ground albedo, are controlled as effectively as possible, and all relevant meteorological data is recorded.

The rapid change in the system configuration allows different parameter variations to be compared under virtually identical conditions. At the same time, yield measurements can be collected over a longer period of time for a wide range of configurations of slope inclination, slope orientation, module inclination, and row spacing. The corresponding data will subsequently be freely available for viewing.

Concept and Realization

Both generations of the facility were built on a scale of 1:12 and designed so that they can be easily set up at other locations (explanation video on the first-generation model facility).

Implementation of the first generation

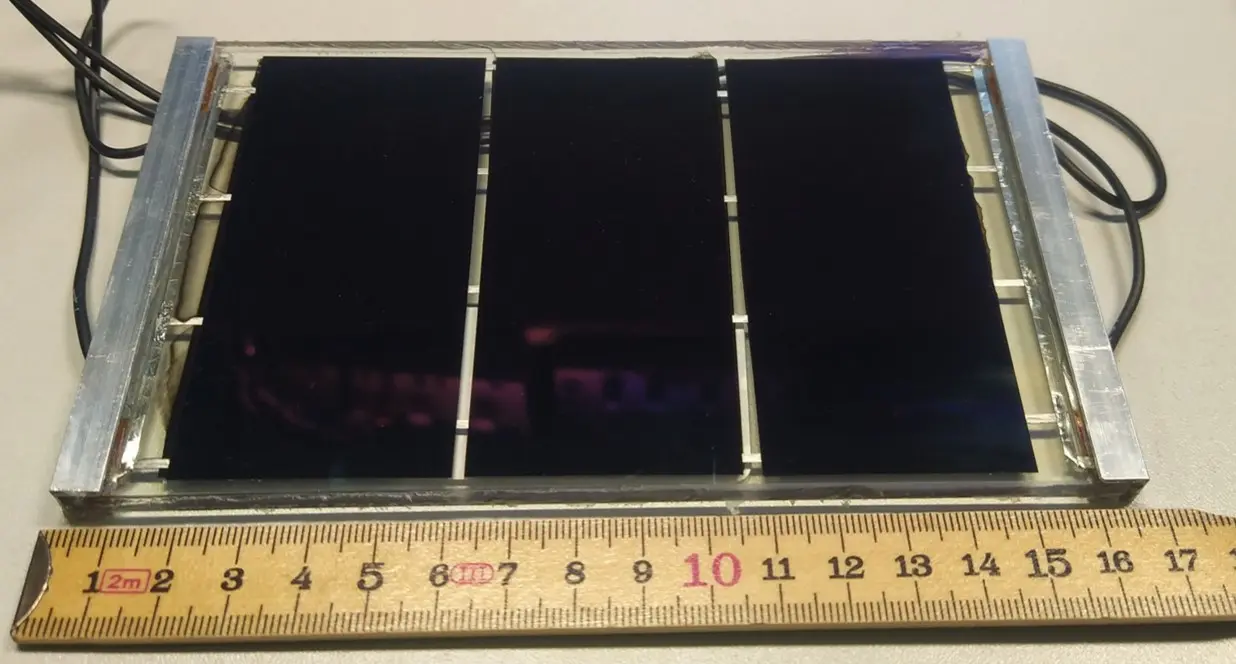

It has three rows, each with seven bifacial modules. In order to obtain separate measurement values for the front and back, these are designed as two monofacial modules, each measuring 96 mm x 160 mm (Figure 1). Of the 42 installed modules, 24 are active and can be measured using precise electronic measuring equipment. The remaining modules are identical dummies.

The row spacing can be adjusted using two trapezoidal spindles under the structure. While the middle row is permanently installed, the northern and southern rows are moved using stepper motors to measure the yield at different shading angles (10°-30°). The row spacing can be adjusted between 115 mm and 700 mm. The module inclination is adjusted directly via stepper motors at the respective row end with a relative (to the horizontal) angle range of −40° to 90°. The slope inclination (angle of attack of the entire structure) can be adjusted via two linear actuators in an angle range of 0°–40°.

To prevent snow from building up on the experimental facility, heating mats are installed that are activated when precipitation or low temperatures occur. To ensure precise positioning, all stepper motors are equipped with an encoder and are periodically referenced. All actuators are controlled via a central control system using Modbus RTU.

The positions to be approached (row spacing, module inclination, and slope inclination) are defined via a configuration file. Once the positions have been reached, the measurement is triggered, with each specified module measuring in sequence the module power (Pmpp), open-circuit voltage (Uoc), and short-circuit current (Isc).

Second-generation design with rotating base

A second generation of the system has been installed since October 2025. The basic mechanics of the mini PV system are similar in both versions. Compared to the first generation, the second generation of the system consists of five rows of modules, with rows 2 and 4 designed as dummy rows. Based on the findings from the operation of the first generation of the system, the system has been optimized in various areas for more stable operation under alpine weather conditions.

In addition, it now has a rotating substructure, so that the slope orientation (azimuth) can now also be varied automatically between 90° (east) and 270° (west). This allows different combinations of slope inclination and orientation to be systematically measured. The mechanical design is correspondingly more complex, especially in the area of the substructure (see Figure 2). To measure the yield at different shading angles, the row spacing between the modules can be adjusted between 115 mm and 280 mm.

The measurement cycles of the second generation have been greatly accelerated: instead of approximately every five seconds as before, one measurement per second is now performed. Four modules in a specific position (row spacing, module inclination, slope inclination, and slope orientation) are measured simultaneously (Uoc, Isc, and Pmpp).

Data acquisition

Data collection takes place simultaneously with the measurements. In addition to the measured module yields of the positions examined, the following additional data is appended to the measurement data: all weather data as well as diffuse and direct radiation, albedo of the snow, and, where available, yield data from a normal-sized comparison module of the large test facility. This allows the various influencing factors to be broken down later and generally valid results to be achieved.

Commissioning of the PV systems

The first generation of the system was installed in spring 2023 on the container roof of the existing alpine PV test facility on the Totalp in Davos and operated until summer 2025. Since the end of September 2025, the second, rotating mini PV system has been installed at the same location, with which the measurement campaigns will be continued in the winter half-year 2025/26.

- Video 1: Time-lapse of the second-generation mini PV system (December 14, 2025)

- Video 2: Time-lapse of a drone shot of the second generation with variation in slope orientation

Results Winter 2023/24 – first generation

A initial report on the results from the operation during the winter season 2023/24 has already been published. The measured values were validated using the large test plant set up at the same location (see Figure 3).

The measured yields over parts of this measurement period were compared with yield simulations for about 80 different plant configurations using the commercial software PVSyst, which was fed with measured weather data from the same period.

In particular, when following the SFOE recommendations regarding the albedo values to be used, it was found that the yields were underestimated by 7 to 16%, depending on the plant configuration. This is partly relativized by a countervailing, systematic source of error on steep slopes. While this report compared specific measurement values and shorter time periods, evaluations of absolute yields over the entire winter season are in progress and will be published as soon as possible.

With the second generation of the mini PV system, which has been in operation since fall 2025, these analyses can now be extended to additional configurations with variable slope orientation.

Related Projects

Project Funding and Thanks

We would like to thank the Hauser Foundation for funding this project.