Food Technology Research Group

New approaches to food processing are required to address the current challenges in feeding the global population.

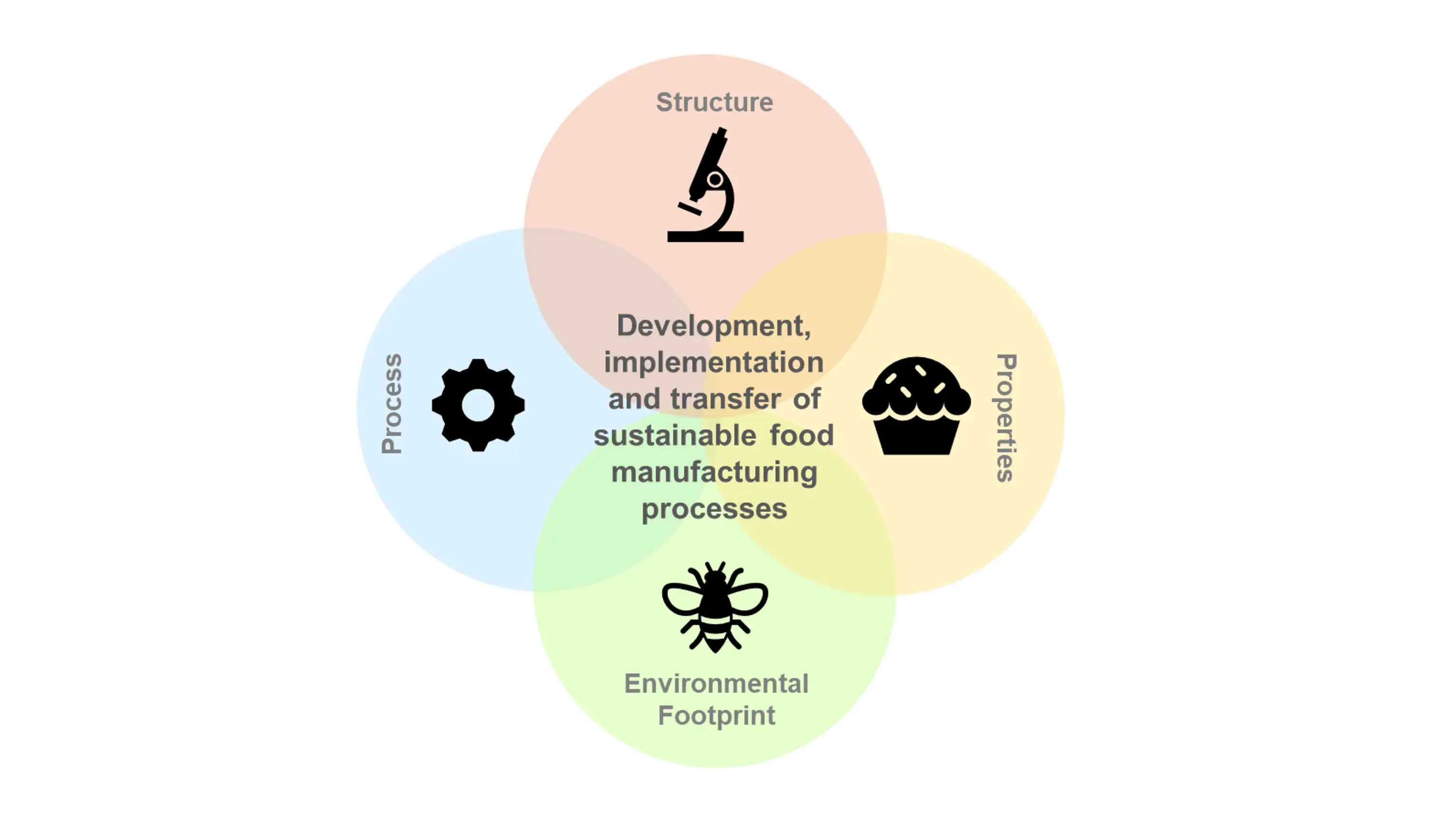

The Food Technology Research Group focuses on the development, implementation and transfer of sustainable manufacturing processes.

Feeding the world's population is a significant driver of global resource consumption, in the process causing around 20-30% of all environmental effects (Tukker et al., 2006). At the same time, a third of all food is thrown away. Malnutrition and overeating are among the greatest health challenges of our time, while consumption patterns and consumer trends are changing significantly. In order to meet the resulting expectations, needs and preferences of consumers and at the same time to use natural resources sparingly, new approaches to food processing and the use of advancing digitisation are required.

The Food Technology Research Group deals with issues relating to the development, implementation and evaluation of sustainable food production processes. The foundation of all developments is the understanding of the interrelationships between process, structure and properties of food, and their effect on the environment as viewed through the lens of materials science. The focus is on improving process technologies in terms of their ecological footprint by using raw materials that are as sustainable as possible, increasing both the efficiency and the value of by-products. At the same time, it must be ensured that the resulting food is nutritionally valuable, sensorially attractive, safe and economically viable. Suitable methods are currently being developed to assess the effects achieved.

Areas of Research

Our research focuses on the following two key areas:

Sustainable food processing chains

A third of all food is not consumed due to loss or as waste. It is important to minimise these losses and at the same time, develop new raw materials through suitable processing steps.

Food production, and especially food waste, is a much-discussed topic because a third of global energy consumption is now used to produce food, a third of which is thrown away. These 1.3 billion tonnes of food waste, which are accrued annually, correspond roughly to a tower 1,800 km high with the footprint of a football field. The amount of food waste causes 3 Gt of CO2 emissions, which is the total greenhouse gas emissions of both Russia and Brazil combined.

This major challenge with respect to ecological sustainability, coupled with the new technological possibilities of today, raises intriguing questions. What measures can be used to optimise manufacturing processes and thus to avoid food losses? What new raw materials are available and how can they be processed? What are the food safety challenges, for example, if we want to recycle food by-product streams? How can the new approaches be implemented profitably? And finally, what contribution can advancing digitisation make to solving complex questions? In order to answer these multi-faceted questions, collaboration between the various actors in the food value chain and various research disciplines is essential.

The Food Technology Research Group of the Institute of Food and Beverage Innovation at the ZHAW develops processing steps that maximise the use of raw materials, allow the recycling and return of by-product streams into the food chain, and enable the processing of new protein sources that replace unsustainable raw materials. In addition, the group develops evaluation methods to quantify the effects achieved and researches more intelligent processing operations through digitisation.

Improved nutritional profile

The consumption of processed foods is increasing all the time. It is therefore all the more important to reconcile the high demands on the nutritional and sensory quality of the products with food safety and sustainability.

Worldwide, one in three adults is overweight, while one in seven people goes to bed hungry. It is important to improve the current state of affairs of our food system and to offer all consumers an enjoyable and varied range of healthy food products.

Food should be processed to a minimum degree and largely retain its natural structure and composition, while minimising contamination and guaranteeing food safety. To this end, we develop manufacturing processes for processed foods with improved nutritional properties, which make it possible to increase the fibre content of the food and to reduce the sugar and fat content, while maintaining sensory quality and product safety.

Since food preparation outside of the home is becoming increasingly important, it is also necessary and sensible to optimise the quality of the food provided. In order to achieve this, evaluation tools have been developed over the past few years and expertise and training concepts have been established.

Infrastruktur

With our diverse range of processing and analysis equipment in our pilot plant, we can mimic a large number of food production processes at the laboratory and pilot scale and are able to analyse the resulting food products.

Publications

-

Pannen, Sarah T.; Chevillard, Elsa; Chatelan, Angeline; Marques-Vidal, Pedro; Stringhini, Silvia; Vorburger, Robert; Rohrmann, Sabine; Steinemann, Nina; Sych, Janice; et al.,

2025.

Nutrients.

17(9), pp. 1555.

Available from: https://doi.org/10.3390/nu17091555

-

Husmann, Cyrill; Schmid, Tamara; Waser, Chiara; Kaelin, Ivo; Hollenstein, Lukas; Müller, Nadina,

2025.

Crystallized pickering emulsions from plant oil as a local alternative to palm oil.

Foods.

14(1), pp. 104.

Available from: https://doi.org/10.3390/foods14010104

-

Schmid, Tamara; Kinner, Mathias; Stäheli, Luca; Steinegger, Stefanie; Hollenstein, Lukas; De la Gala, David; Müller, Nadina,

2024.

Effect of press cake-based particles on quality and stability of plant oil emulsions.

Foods.

13(18), pp. 2969.

Available from: https://doi.org/10.3390/foods13182969

-

Tran, Thi Khanh Linh; Salvatore, Ivana; Geller, Joel; Theodoracakis, Emmanuelle; Ullrich, Lisa; Chetschik, Irene,

2024.

Molecular aroma composition of vanilla beans from different origins.

Journal of Agricultural and Food Chemistry.

72(34), pp. 19120-19130.

Available from: https://doi.org/10.1021/acs.jafc.4c04775

-

André, Amandine; Hecht, Katrin; Mischler, Sandra; Stäheli, Luca; Kerhanaj, Fllanza; Buller, Rebecca; Kinner, Mathias; Freimüller Leischtfeld, Susette; Chetschik, Irene; Miescher Schwenninger, Susanne; Müller, Nadina,

2024.

Food Research International.

186(114364).

Available from: https://doi.org/10.1016/j.foodres.2024.114364

Project Collaboration

We offer various opportunities for project collaboration. Projects are carried out in the form of research projects, development projects, services or student projects, such as semester papers, Bachelor’s theses, or Master’s theses.

For more information on project collaborations

For project inquiries, please contact Dr. Nadina Müller

Team