Smart Services and Operations

Erkenntnisse gewinnen, Mehrwert schaffen und Innovationen in Geschäftsprozessen und Dienstleistungen fördern

Wir nutzen modernste datengesteuerte Technologien, um Geschäftsprozesse zu optimieren und intelligente Lösungen zu entwerfen, die sowohl in der Industrie als auch in der Dienstleistungsbranche Wert schaffen und die Transformation vorantreiben. Unsere quantitativen Service Engineering und Operations Management Methoden fördern digitale Innovationen und stärken die Entscheidungsintelligenz. Unsere Strategie betont kundenorientierte und vorteilhafte Wertschöpfung, um das Smart-Service-Engineering und die operative Optimierung zu verbessern und nachhaltiges Wachstum und Effizienz zu fördern.

Forschung & Projekte

Analytische Wert- & Umsatz-Modellierung für Smart Services

Wir identifizieren Smart-Service-Konfigurationen mit maximalem wirtschaftlichem Nutzen – für Anbieter und Kunden.

Mit unseren Analysemodellen bewerten wir systematisch die Wertpotenziale von Smart Services und entwickeln tragfähige Umsatzmodelle. Dabei berücksichtigen wir sowohl die Kundenakzeptanz als auch das Risiko auf Anbieterseite – und schaffen so die Grundlage für wirtschaftlich erfolgreiche Serviceinnovationen.

Im Forschungsprojekt BePro-CEND arbeiten wir gemeinsam mit Berhalter AG, Bühler AG und maxon international ltd an der Optimierung der Wertschöpfung durch zirkuläre Dienstleistungen in industriellen Anwendungen.

- Entwicklung des Abfallwirtschafts-Ökosystems mit Hilfe eines intelligenten, vernetzten Produkt-Service-Systems (PSS)

- Meierhofer, Jürg; Pascher, Nikola; Wulf, Jochen, 2024. The value of solving pains

- Meierhofer, Jürg; Heitz, Christoph, 2023. On the value of data in industrial services: How to optimize value creation by reconfiguration of operant resources

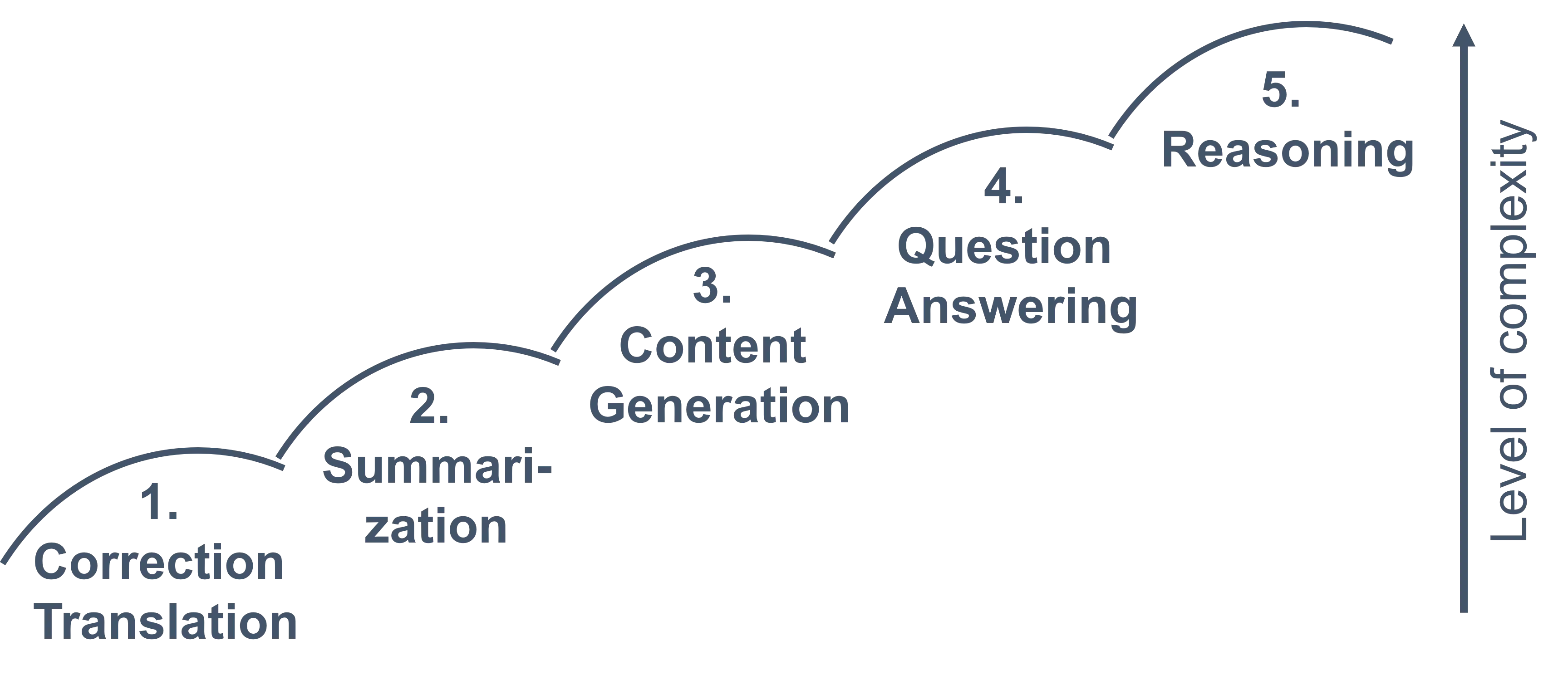

GenAI für technische Dienstleistungen und operative Unterstützung

Wir nutzen Large Language Models, um technische Dienstleistungen und die operative Unterstützung im Technologiesektor zu automatisieren, indem wir Prototypen entwerfen und testen, die die Effizienz steigern, Betriebskosten senken und die Serviceverfügbarkeit verbessern. Im Projekt Large Language Models as a Service in Marketing haben wir beispielsweise die Workflows zur kanalspezifischen Inhaltsanpassung bei einem Marketingdienstleister automatisiert.

- Wulf, Jochen; Meierhofer, Jürg, 2024. Exploring the potential of large language models for automation in technical customer service

- Wulf, Jochen; Meierhofer, Jürg. 2025. The Impact of Large Language Models on Task Automation in Manufacturing Services

- Wulf, Jochen; Meierhofer, Jürg, 2024. Wie LLMs die Automatisierung im Kundendienst fördern

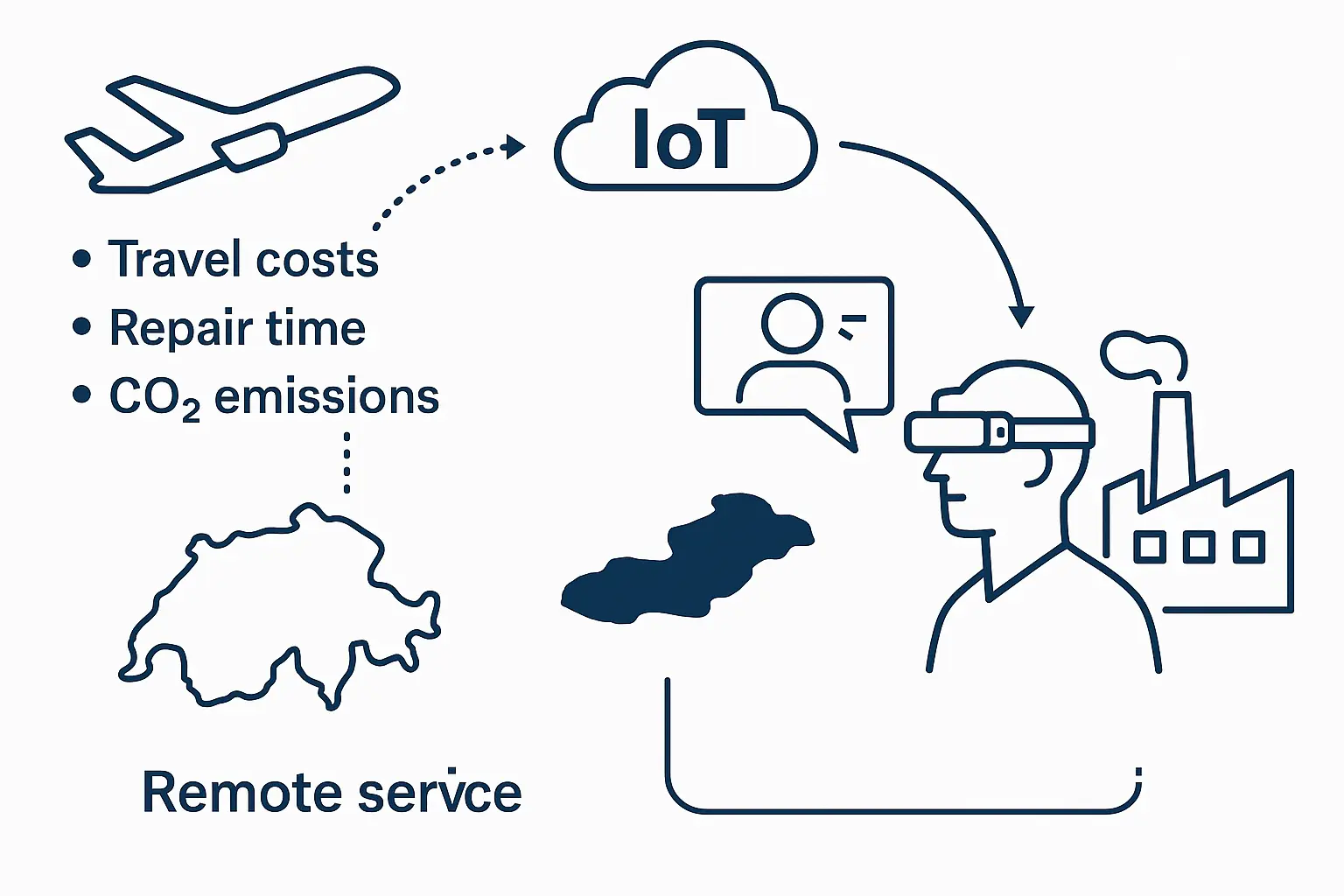

Wert für Umwelt und Gesellschaft durch Smart Services

Wir erforschen den ganzheitlichen Wert von Smart Services – ökonomisch, ökologisch und gesellschaftlich.

Auf Basis unserer Methoden zur Analyse von Wertschöpfung und Umsatzpotenzial durch Smart Services erweitern wir unsere Forschung um die Bewertung ihrer Nachhaltigkeitswirkung. Unser Ansatz kombiniert Wirtschaftlichkeitsmodellierung mit Nachhaltigkeitsbewertung, um Servicekonfigurationen zu identifizieren, die einen mehrdimensionalen Nutzen stiften.

Im IoT Sustainability Lab (Interreg ABH) entwickeln und testen wir beispielsweise intelligente Servicemuster für industrielle Anlagen, die wirtschaftliche Effizienz mit ökologischer Verantwortung und sozialem Mehrwert verbinden.

- Sustainable Mobility Lab (Interreg ABH)

- Meierhofer, J., Wulf, J., Gallina, V., Gal, B., & Eisl, S. (2024). Optimising data driven value creation in industrial services incorporating circularity.

- Weisskopf, S., Meierhofer, J., & Sordini, F. V. (2024). Quantitative Models for Sustainable Smart Services in the Building Industry

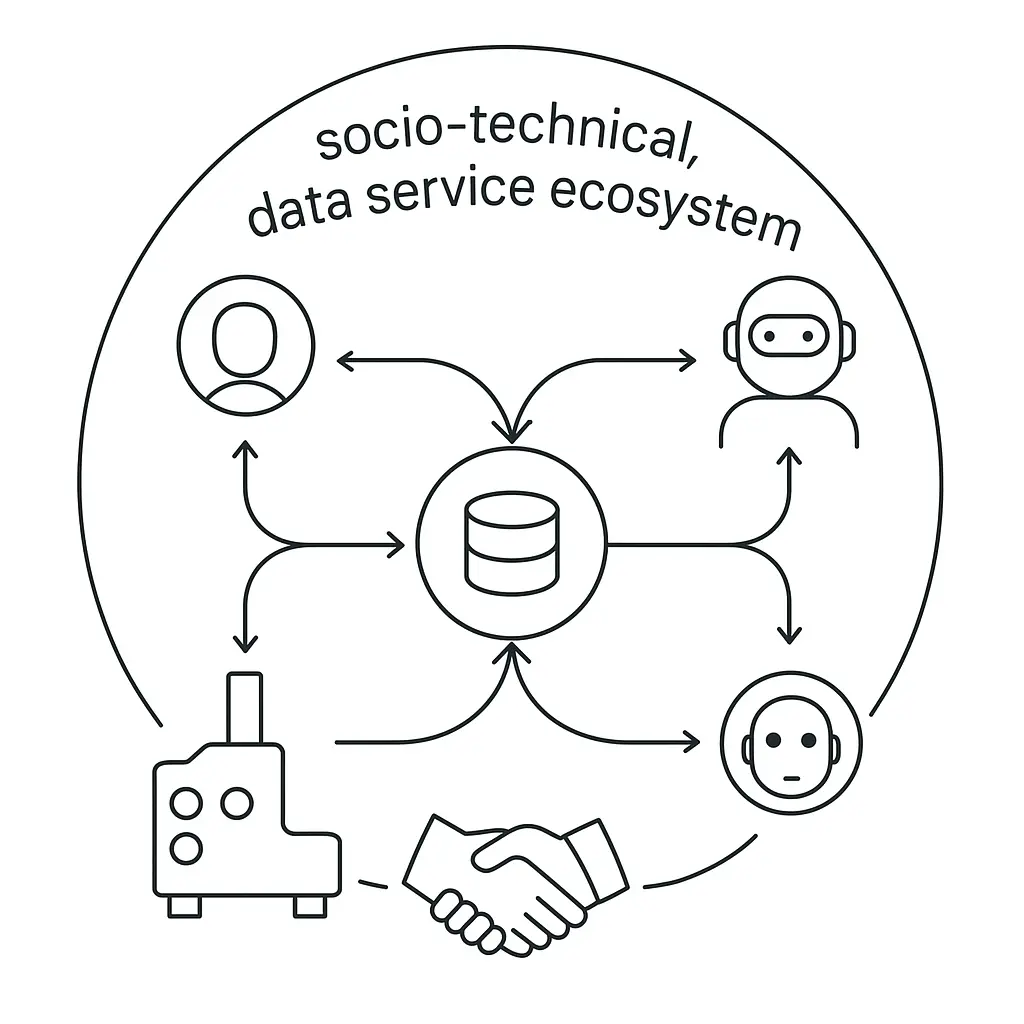

Aktivierung datengetriebener Wertschöpfung in Ökosystemen: Ein Gestaltungsansatz in Bezug auf technische und regulatorische Faktoren

Wir schaffen die Grundlagen für datengetriebene Wertschöpfung in vernetzten Geschäftsökosystemen.

Im Projekt Data Sharing Framework entwickeln wir konzeptionelle und methodische Ansätze, die den strukturierten, kontrollierten und nutzenorientierten Austausch von Daten zwischen Organisationen ermöglichen. Durch den Einsatz fortschrittlicher Analysetechniken bewerten wir das wirtschaftliche Potenzial des organisationsübergreifenden Datenaustauschs quantitativ – und machen so den Wert von Daten sichtbar und nutzbar.

- Benedech, R. A., Vogt, H., Meierhofer, J., Kugler, P., Strittmatter, M., Dobler, M., Meyer, J., & Treiterer, M. (2023). Data Sharing Framework für KMU

- Meierhofer, J., Kugler, P., Vogt, H., Dobler, M., Benedech, R., Strittmatter, M., & Treiterer, M. (2022). Improving Service Value Creation for Manufacturing SMEs by Overcoming Data Sharing Hurdles in Ecosystems

Smartere Ablaufpläne, schnellere Produktion: Algorithmische Planung in Job-Shops

In der kundenspezifischen Blechherstellung ist die Planung von Job-Shops komplex und reaktiv, da jeder Auftrag einerseits eine Massanfertigung ist, und andererseits einen kurzen Liefertermin verlangt. Unser Projekt zeigt, wie adaptive Planungsalgorithmen, die Jobsequenzen dynamisch optimieren, diese Herausforderung in einen Wettbewerbsvorteil verwandeln können: Wir liefern schnell und genaue Liefertermine für eine schnelle Kundenreaktion und reagieren sofort auf Änderungen wie neue Aufträge oder Maschinenausfälle. Die Auswirkungen: 5–10% kürzere Vorlaufzeiten, 10% mehr abgeschlossene Aufträge sowie mehr Zuverlässigkeit und Effizienz – was die Leistung und die Zufriedenheit der Mitarbeiter erhöht.

- Adaptive Production Planning Systems for Fast Decision Support

- Gröflin, Heinz; Klinkert, Andreas, 2009. A new neighborhood and tabu search for the blocking job shop. Discrete Applied Mathematics. 157(17), S. 3643-3655.

- Gröflin, Heinz; Klinkert, Andreas; Pham Dinh, Nguyen, 2008. Feasible Job Insertions in the Multi-Processor-Task Job Shop. European Journal of Operational Research. 185(3), S. 1308-1318.

- Gröflin, Heinz; Klinkert, Andreas, 2007. Feasible insertions in job shop scheduling, short cycles and stable sets. European Journal of Operational Research. 177(2), S. 763-785.

Menschen in Smart Operations

Operations soll Menschen effektiv unterstützen – nicht umgekehrt: Layoutplanung verbessert die Ergonomie und die Sicherheit, während durchdachte Dienstpläne und Ablaufplanungen sicherstellen, dass die Mitarbeiter befähigt sind, ihr Bestes zu geben. Wenn Menschen von den richtigen Prozessen unterstützt werden, gedeihen Produktivität und Zufriedenheit.

- Schmid, Daniel; Herrmann, Thomas, 2024. Human-zentrierte und resilienzfördernde Digitalisierung. ZHAW Industrie 4.0 Blog

- Optimierung von Personaleinsätzen in der Pflege

- De Martinis, Valerio; Huber, Marius; Herrmann, Thomas; Wüst, Reimond Matthias, 2023. Diskriminierungsfreie Ansätze für die Tourenplanung des Lokpersonals. ETR – Eisenbahntechnische Rundschau. 2023(4), S. 2-7

- Sedding, Helmut A., 2024. Mixed-model moving assembly line material placement optimization for a shorter time-dependent worker walking time. Journal of Scheduling. 27(3), S. 257-275

- Sedding, Helmut A., 2020. Line side placement for shorter assembly line worker paths. IISE Transactions. 52(2), S. 181-198

Optimierung des Flughafenpersonals: Unser Auto-Rostering-Projekt mit der Swissport International AG zeigt, wie unsere automatisierten Personalplanungsalgorithmen den Flughafenbetrieb durch effiziente, faire und anpassbare Schichtpläne verbessern. Durch die Ausgewogenheit betrieblicher Anforderungen, Verträge und Mitarbeiterpräferenzen bietet das System eine schnellere Planung, bessere Dienstpläne, weniger Aufwand und erhebliche Kosteneinsparungen – und zeigt die Leistungsfähigkeit der Technologie bei der Verwaltung komplexer Mitarbeiterbedürfnisse.

- Automatisierte Dienstplanung an Flughäfen

- Fusek, Peter, 2023. Airport ground staff scheduling : making impact with a high-performance business application based on integer programming. In: Gurobi Live! The Decision Intelligence Summit, Barcelona, Spain, 18-19 October 2023.

- Fusek, Peter; Klinkert, Andreas, 2019. Airport ground staff scheduling: a real-world business application. In: 30th European Conference on Operational Research, Dublin, Ireland, 23-26 June 2019

- Züger, Armin; Klinkert, Andreas, 2010. Am Montag möchte ich nicht arbeiten : Personaleinsatzplanung. Impact. (11), S. 36-37

Responsible Operations treibt nachhaltige Werthaltung

Responsible Operations integriert ethische, ökologische und soziale Aspekte in die Kerngeschäftspraktiken. Dies ermöglicht es, Abfall zu reduzieren, den Ressourcenverbrauch zu optimieren und die Nachhaltigkeit zu unterstützen, indem operative Entscheidungen an die langfristige Wertschöpfung angepasst werden und gleichzeitig negative externe Effekte minimiert werden.

Effizienzboost: Der Lean-& Digital-Vorteil in Operations

Operations erreichen eine dauerhafte Effizienz, indem sie Lean-Prinzipien mit digitalen Technologien kombinieren. Lean strafft Prozesse durch die Beseitigung von Nichtwerschöpfendem, während digitale Tools – wie fortschrittliche Analysen und KI-gestützte Ressourcenplanung – die Sichtbarkeit verbessern und optimale Entscheidungen ermöglichen. Gemeinsam beschleunigen sie die Verbesserung, steigern die Agilität und schaffen widerstandsfähige, leistungsstarke Operationen.

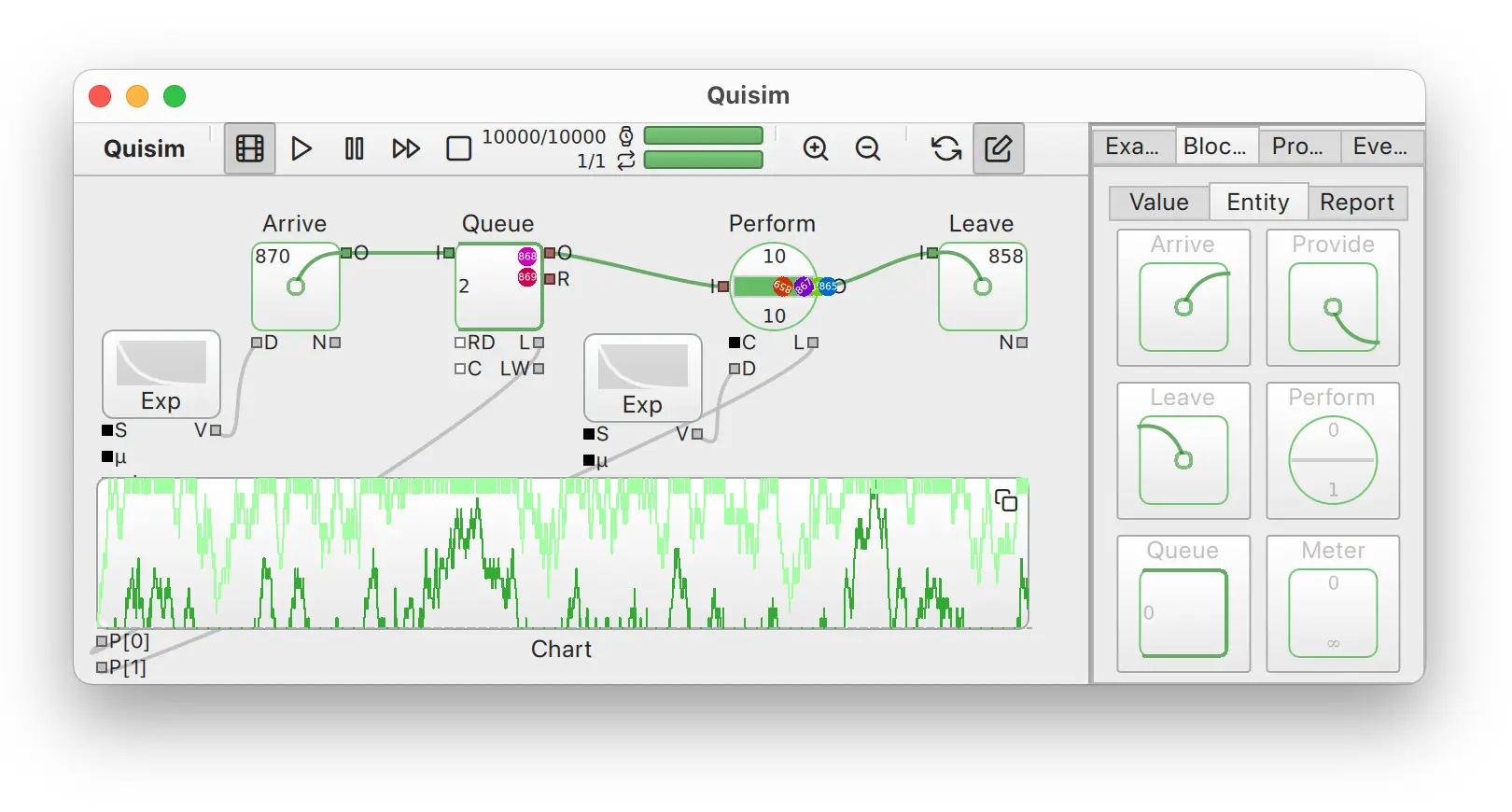

Digitale Zwillinge und Simulation: Ein integraler Ansatz zur Produkt- und Prozessentwicklung

Digitale Zwillinge – virtuelle Nachbildungen realer Systeme – verändern die Produkt- und Prozessentwicklung. Kontinuierlich mit echten Daten aktualisiert, ermöglichen sie schnellere, intelligentere Entscheidungen, indem man Designs vor der Implementierung simuliert und optimiert. Eine Masterarbeit der Schmid Elektronik AG zeigt den Nutzen digitaler Planungszwillinge zur Automatisierung der Produktionsplanung. Dies führt zu erheblichen Zeiteinsparungen, erhöhter Liefersicherheit und unterstreicht das Potenzial digitaler Tools, um menschliche Planungseffizienz zu erreichen oder zu übertreffen.

- Flugnetzwerk-Simulation bei Swiss International Air Lines

- Meierhofer, Jürg; Schweiger, Lukas; Lu, Jinzhi; Züst, Simon; West, Shaun; Stoll, Oliver; Kiritsis, Dimitris, 2021. Digital twin-enabled decision support services in industrial ecosystems. Applied Sciences. 11(23), S. 11418

- Hosang, Jürg, 2002. Lagerhaltung eines Handelsprodukts: Modellierung und Optimierung mittels statistischer Datenanalyse und Discrete Event Simulation. Bulletin der Schweizerischen Gesellschaft für Statistik

News

Keine Nachrichten verfügbar.

Team

“Der beste Weg um die Zukunft vorherzusagen ist, sie zu erfinden.” ― Alan Kay