Microalgae as sustainable source of protein for animal feed?

Protein from microalgae is considered as a sustainable alternative to soy in animal feed production. But what is the actual emission reduction potential of these innovative forms of production? A recently published study by the Life Cycle Assessment research group sheds light on this and shows that it all depends on scale and method.

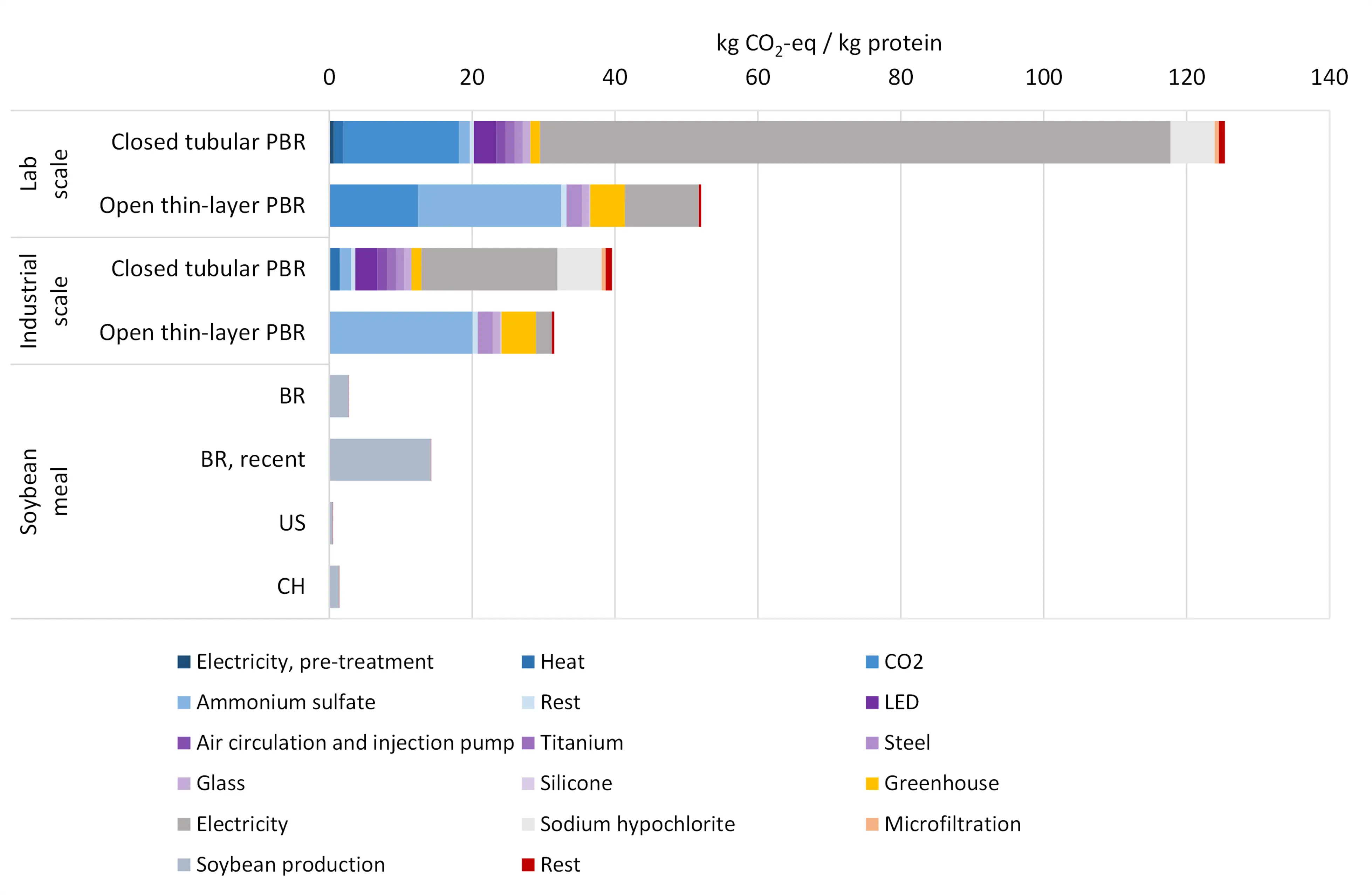

The study, which was conducted as part of the project Apropos, compares microalgae production from two different production systems: a closed tubular photobioreactor (PBR) and an open thin-layer PBR. The focus was to analyse lab-scale data and extrapolate to industrial-scale production scenarios to compare environmental impacts to those of soybean protein. The results show: scaling microalgae production reduces life cycle greenhouse gas (GHG) emissions per kilogram of protein by up to 73% for closed tubular systems and by up to 40% for open thin-layer systems – a reduction necessary to reach the comparatively low emission levels of soybean protein (see Graph). Key assumptions for the industrial scale scenario are improved electricity efficiency and a burden-free CO2 source to feed the algae.

The two microalgae production systems differ in their setup, leading to trade-offs between different environmental impact categories. The closed system uses LEDs to provide the algae with sufficient light and requires higher pumping pressure to circulate the water through tubes. Therefore, it has a considerably higher electricity consumption compared to the open system, causing higher GHG emissions. Another main difference between the two systems is the nutrient medium, in which the microalgae are cultivated. In the closed tubular PBR, the microalgae biomass was cultivated in potato wastewater, which is rich in ammonium sulphate but requires a pre-treatment with membrane filtration and UV filters. In contrast, the microalgae in the open thin-layer PBR were cultivated using a standard mineral medium containing chemically produced ammonium sulphate. For certain impact categories such as ecotoxicity, the open system therefore showed significantly higher impacts, as it is exposed to losses and therefore requires large amounts of mineral medium and with that, large amounts of ammonium sulphate. Hence, the potato wastewater was generally found to be the recommendable nutrient medium as it naturally contains ammonium and reduces the amount of chemically produced ammonium needed.

Circling back to the question whether protein from microalgae should be used for animal feed in order to replace soybean protein, the answer is – as so often – ‘it depends’. If microalgae protein is compared to imported protein from soybeans cultivated in Brazil, impacts can be reduced in certain environmental categories, particularly if the production of algal protein would lead to a reduction of land use change and pesticide application connected to soybean cultivation. For protein from European soybean, however, environmental impacts remain lower than microalgae protein produced with current systems.

A Thank You goes out to the project partners Mariluz Bagnoud from Agroscope and Dominik Refardt from ZHAW who work constantly on the optimisation of algae cultivation.