ZHAW researchers train enzyme that breaks down plastic

The “PETase” enzyme can break down plastic, but it is not very productive. ZHAW researchers are therefore applying “directed evolution” to train the enzyme so that it can be used in future for treating drinking water or biorecycling. Machine learning and a tailor-made robot will now further accelerate this process.

Around 359 million tonnes of plastic are produced every year, of which up to 200 million tonnes end up accumulating in landfill sites or the environment. In the Pacific, for example, an island of plastic waste that is three times the size of Germany has formed. An enzyme could contribute to solving this environmental problem. In 2016, Japanese researchers discovered a protein in a soil sample taken from a PET recycling plant in Osaka that is able to break down PET. It originates from the Ideonella sakaiensis bacterium and presumably resulted as nature’s reaction to the large volume of plastic waste. However large amounts of plastic have only been found in the environment in the last few decades, so that natural evolution has not yet had enough time to develop a perfect solution. The PETase enzyme is thus not productive enough at present to make a relevant contribution to the battle against plastic. A research team headed by Rebecca Buller at the ZHAW Institute of Chemistry and Biotechnology in Wädenswil wants to change this, using “directed evolution”, and now also with the support of a robot and machine learning. “The improved enzyme variants could be used in the treatment of drinking water to break down microplastics. It is also conceivable that they could be used in the biorecycling of PET waste,” says Rebecca Buller.

More efficient enzymes thanks to «directed evolution»

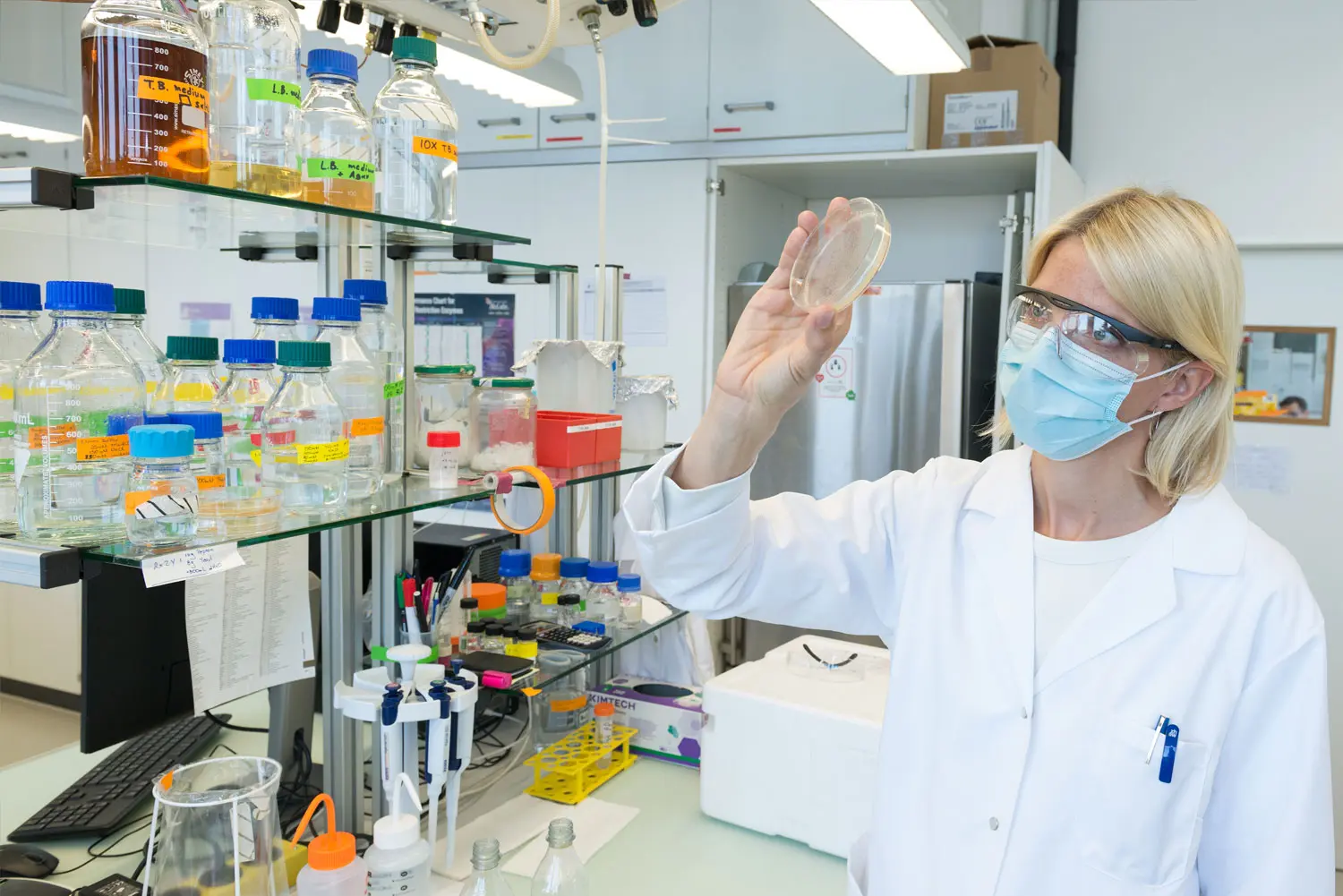

For several months, ZHAW researchers have been working intensively on the development of «PETase» enzymes. They are applying the process of «directed evolution», which was recognised with the Nobel Prize in Chemistry in 2018. This imitates the mechanisms of natural evolution in a laboratory setting in order to improve selected enzyme properties. Sean Hüppi from the ZHAW Institute of Chemistry and Biotechnology is already successfully applying the process for the «PETase» enzyme for his doctoral thesis. He explains that «by rewriting the enzyme’s blueprint, we can produce variants with a slightly different structure». Several hundred enzyme variants have already been produced in this way. Microplastics are exposed to these enzymes by the ZHAW researchers, who then observe which enzyme variant breaks down the plastic the fastest. «We’re already seeing multiple improvements in enzyme activity after the first evolutionary changes,» explains Hüppi. The most efficient enzymes will now be used as the starting blueprint for repeating the procedure.

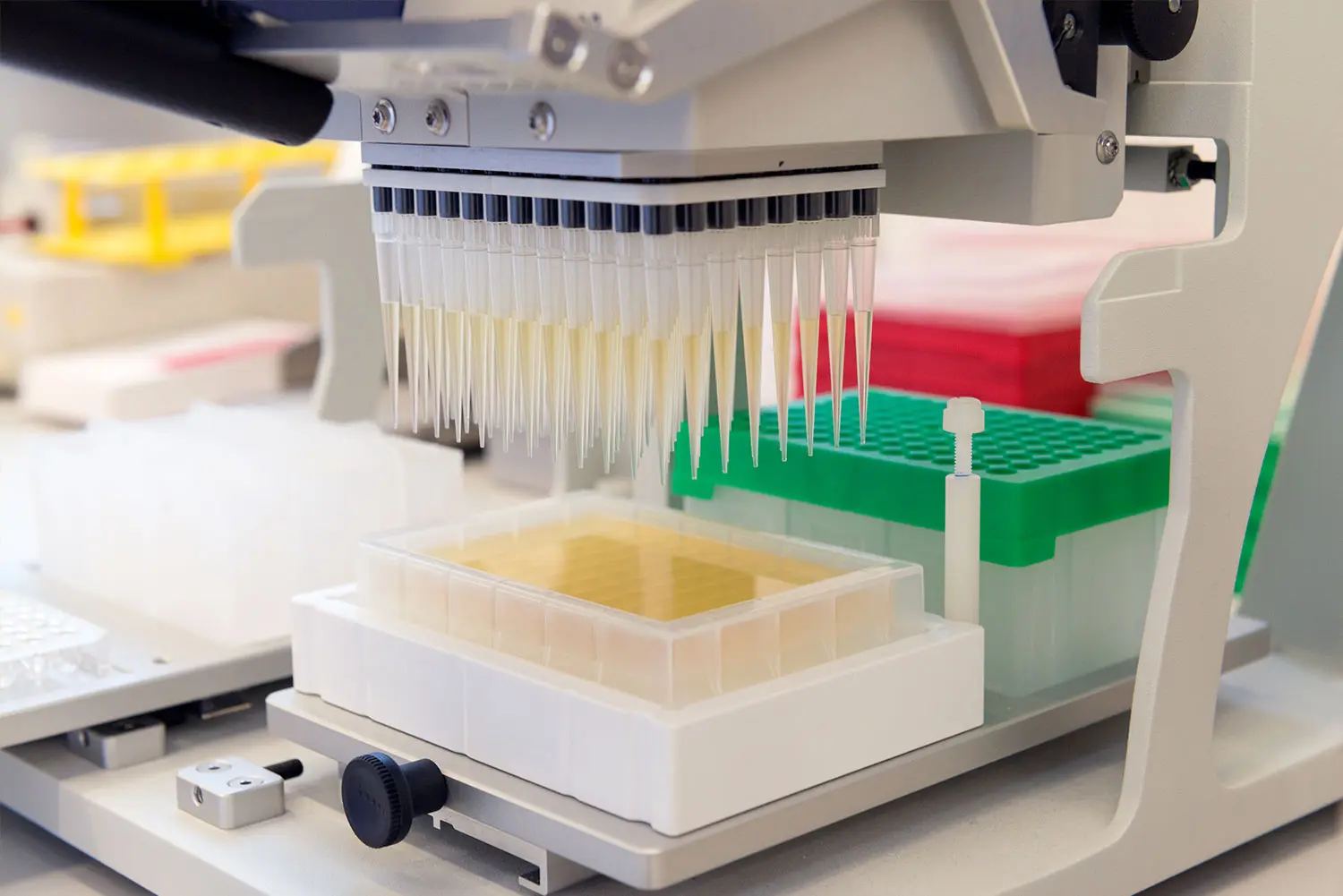

Tailor-made robot and artificial intelligence

While «directed evolution» is already being used in a handful of “PETase» research projects, the ZHAW is now breaking new ground with the use of an innovative robot and artificial intelligence. «We expect that we will once again considerably accelerate the laboratory evolution of PETase through the application of machine learning and an automation platform,» says Rebecca Buller, who is heading the research. The specialised platform for enzyme screening was produced for the ZHAW by the Tecan company, which has its headquarters in Männedorf, Switzerland. Since October 2020, it has been automating laboratory work that had previously been performed by hand. The robot can produce and measure several thousand different PETase variants per week; a person would require almost ten times as much time for this.

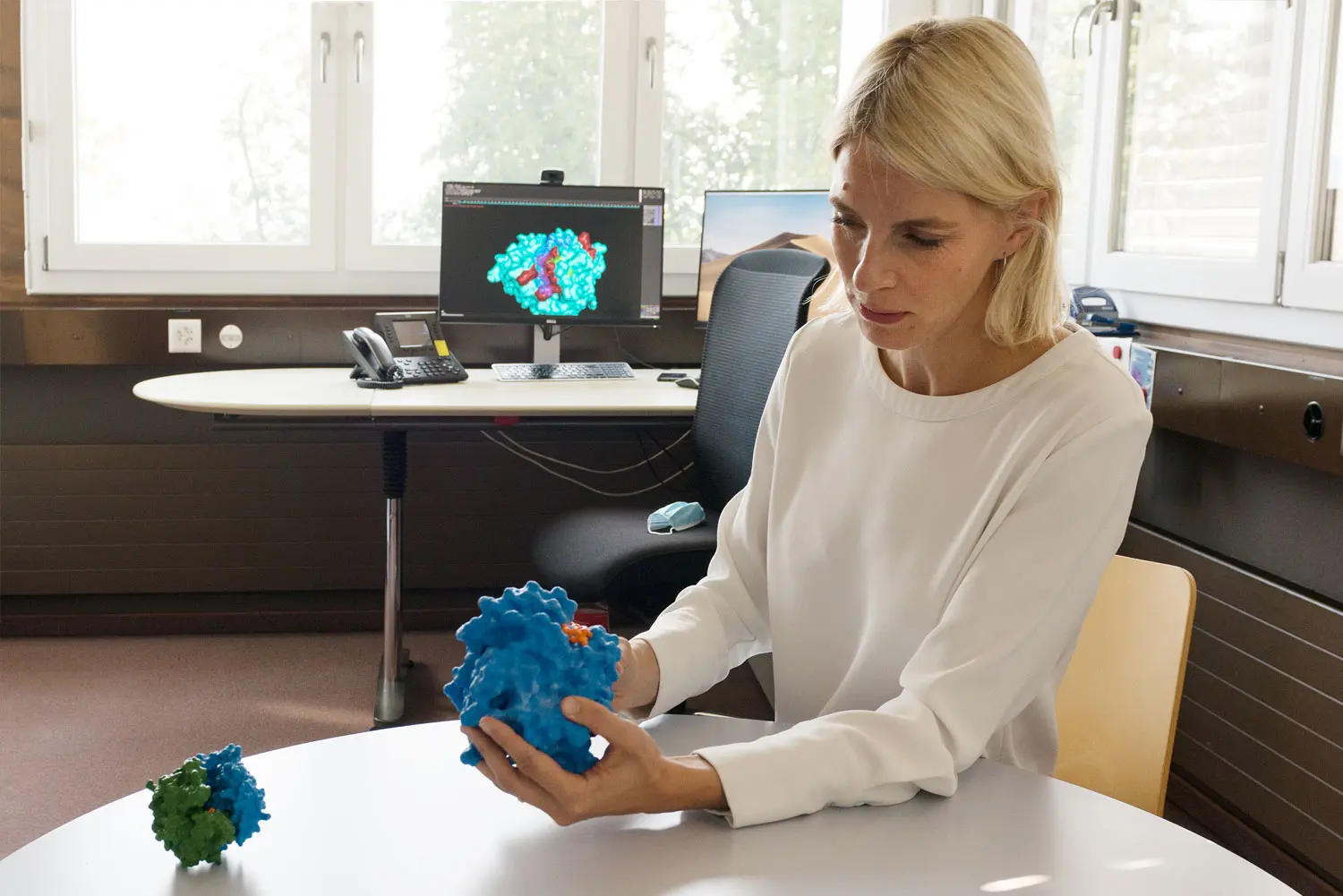

The research group is now also using artificial intelligence for the enzyme development. On the basis of the data gained in the laboratory, the algorithms used make suggestions for optimising the structure of the enzymes, i.e. for the sequence of the enzymes’ natural building blocks: amino acids. This makes it possible to determine, for example, which amino acids in the enzyme play a key role in the rapid degradation of the PET. «Algorithms produce entirely different deductive connections from humans,» says Hüppi. For the development of algorithms and the assessment of data, the ZHAW is working closely with the research group of Andreas Krause at the ETH Zurich’s Institute for Machine Learning. The project is being funded within the framework of «Catalysis», the new National Centre of Competence in Research.