Towards mechanically biocompatible implant materials for pelvic floor repair

At a glance

- Project leader : Prof. Dr. Barbara Röhrnbauer

- Project team : Prof. Dr. Christian Adlhart, Christina Fialová, Jonas Hofmann, Dr. Markus Rimann, Marc Strassmann

- Project status : ongoing

- Funding partner : SNSF (Practice-to-Science / Projekt Nr. 206354)

- Contact person : Barbara Röhrnbauer

Description

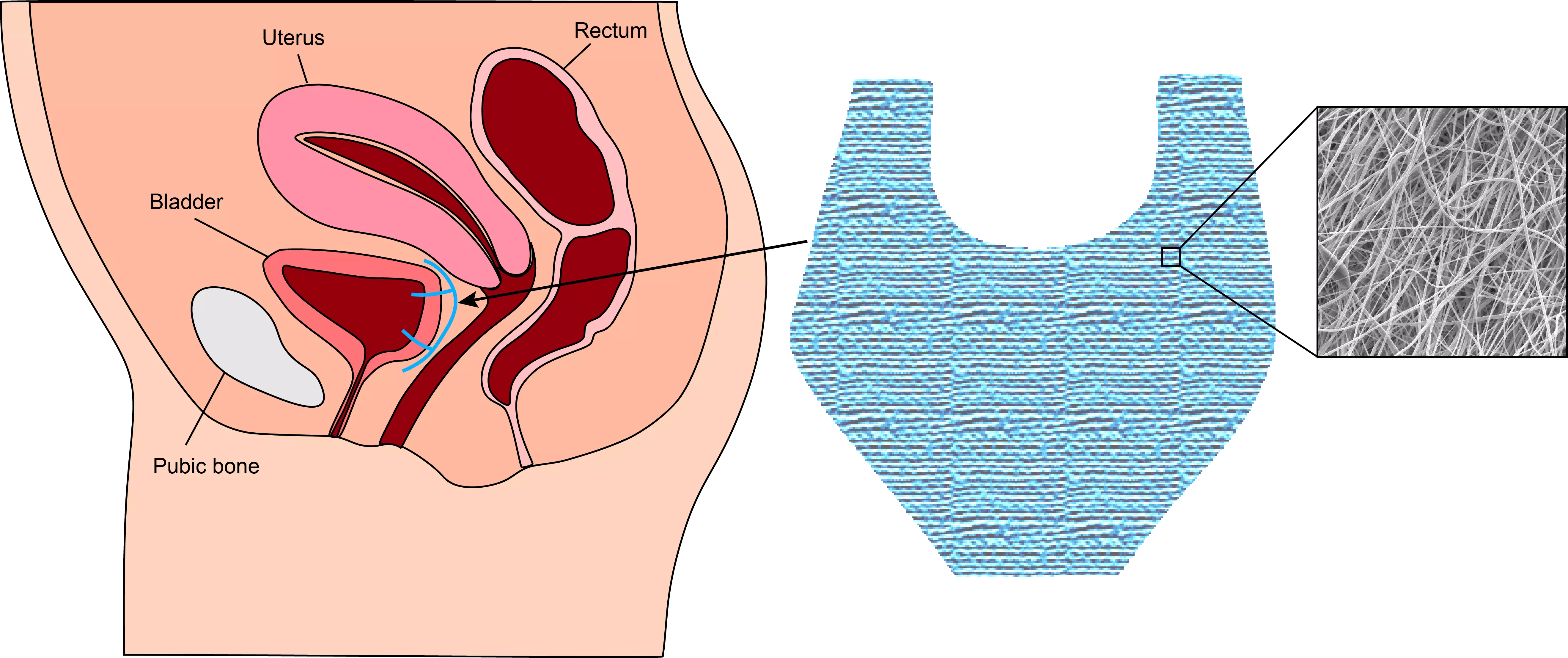

Vaginal meshes, hazard or cure? This has been the topic of a recent PULS broadcasting on Swiss television.In fact, during the last few years, severe and frequent complications, such as erosions, pain and dyspareunia, inparticular related to transvaginal placement of meshes led to numerous lawsuits and in some countries even toa ban of synthetic meshes. But what are the causes for this escalation? Synthetic meshes are applied to treatpelvic organ prolapse (POP). While not being a life-threatening disease, POP is known to strongly impair qualityof life. And the prevalence is high: the lifetime risk for an 80 year old woman undergoing at least one POPsurgery is estimated to up to 20%. Applying traditional native tissue repair, recurrence rates are reported upto 30%, which could be reduced by using meshes. Driven by the success of hernia meshes and encouragedby simplified FDA approval through 510(k), between 2002 and 2008, the market was flushed by a large varietyof meshes and easy-to-use mesh kits for POP repair. The consequences of this rushed market introductionsoon became apparent. Lacking alternatives, national and international gynecological organizations haveaddressed this situation. There is a consensus, that next to clinical factors, implant materials withcarefully tailored mechanical properties will improve safety and performance of POP repair.The proposed research is aimed at a systematic, structural mechanical design of alternative materials forpelvic floor applications with improved mechanical biocompatibility. Due to the immense freedom of design anda resulting, tissue favoring nanostructure, the electrospinning technique shall be applied. The hypotheses to betested are: (1) Different material microstructures lead to different local deformation patterns. (2) Correlationscan be made between quantitative measures of local deformation and cell response. (3) Design criteria can bederived from these correlations for improved implant design due to improved cell compatibility.The core part of this project is a multi-scale experimental mechanical characterization of electrospun networks(ESNs). Based on the expertise and preliminary work of the applicant, test protocols shall be developed tocharacterize the mechanical behavior of ESNs in physiologically relevant loading conditions. Next to the globalmechanical behavior, characteristic local deformation patterns shall be quantified, e.g. the amount of non-affine deformations or local rotation or shear zones. To this end, appropriate image acquisition techniques,such as scanning electron microscopy (SEM) with integrated microtensile testing, and corresponding protocolsfor data extraction and evaluation need to be developed. Candidate materials for this investigation shallbe chosen considering raw materials and parameters reported for studies using ESNs in pelvic floor animalmodels. To investigate the cell response to the local deformation patterns, relevant cell types, e.g. fibroblasts,shall be seeded and grown on these materials. Using a dynamic bioreactor, equivalent physiologically relevantloading conditions shall be applied as for the mechanical tests. The interdisciplinary parts of (i) ESN tailoringand production and (ii) cell compatibility and response testing shall be performed through ZHAW-internalcollaborations. Mechanical procedures shall confirm hypothesis 1: different microstructures lead to differentlocal deformation patterns. Subsequently, quantitative measures describing the local deformations of the ESNand the according cell response shall be correlated in order to test hypothesis 2. Confirmation shall allow toformulate design criteria leading to specific local deformation patterns, leading to a beneficial cell response andcompatibility. 2-3 new ESN designs shall be specifically tailored to meet these criteria. These materials, aswell as modern polypropylene (PP) meshes as controls, shall be tested according to the same mechanical andbiological protocols in order to test hypothesis 3 for improved mechanical biocompatibility.The expected outcome of this research is a deep understanding of the interplay between mechanics and biologyspecifically directed towards improved pelvic floor implant materials. If hypothesis 3 proves true, this researchwill provide prototype materials, which are faithfully designed regarding their mechanical biocompatibility withthe pelvic floor and represent a basis for efficient animal studies. With the proposed systematic bottom-up designapproach, this research addresses a gap in an environment where materials established for another indication,i.e. hernia repair, were top-down and nearly blindly applied to the pelvic floor with severe consequences.

Publications

-

2024.

Dank Grundlagenforschung zum idealen Netz?.

In:

10. Internationaler Kongress Gynäkologie Update, Universitätsspital Zürich, Schweiz, 25.-27. Januar 2024.