Platform Industry 4.0

Creating intelligent links between manufacturing facilities, products and people allows new processes, business models and services to be developed. This ZHAW platform provides comprehensive support to companies transforming their businesses to the Industry 4.0 model.

Industry 4.0 is disrupting existing value chains and transforming entire industries. Successful implementation of new business models requires expertise from a number of different disciplines.

For that reason, the ZHAW School of Engineering has channelled its Industry 4.0 expertise into one platform, combining know-how from a range of disciplines to create one overarching application.

Key topics and areas of research

The Industrie 4.0 platform combines the broad expertise of over ten institutes from various departments at ZHAW, such as the School of Engineering, the School of Management and Law, and the Department of Life Sciences and Facility Management.

The topic of the fourth industrial revolution permeates all parts of the economy and is therefore interdisciplinary. In research and teaching, ZHAW focuses on the economic needs and challenges of Industrie 4.0, for example in the areas of services and business model transformation. Based on this, the corresponding product and process development takes place, combining the mechanical-physical manifestation of products with the current state and potential of electronic systems (embedded systems) and software.

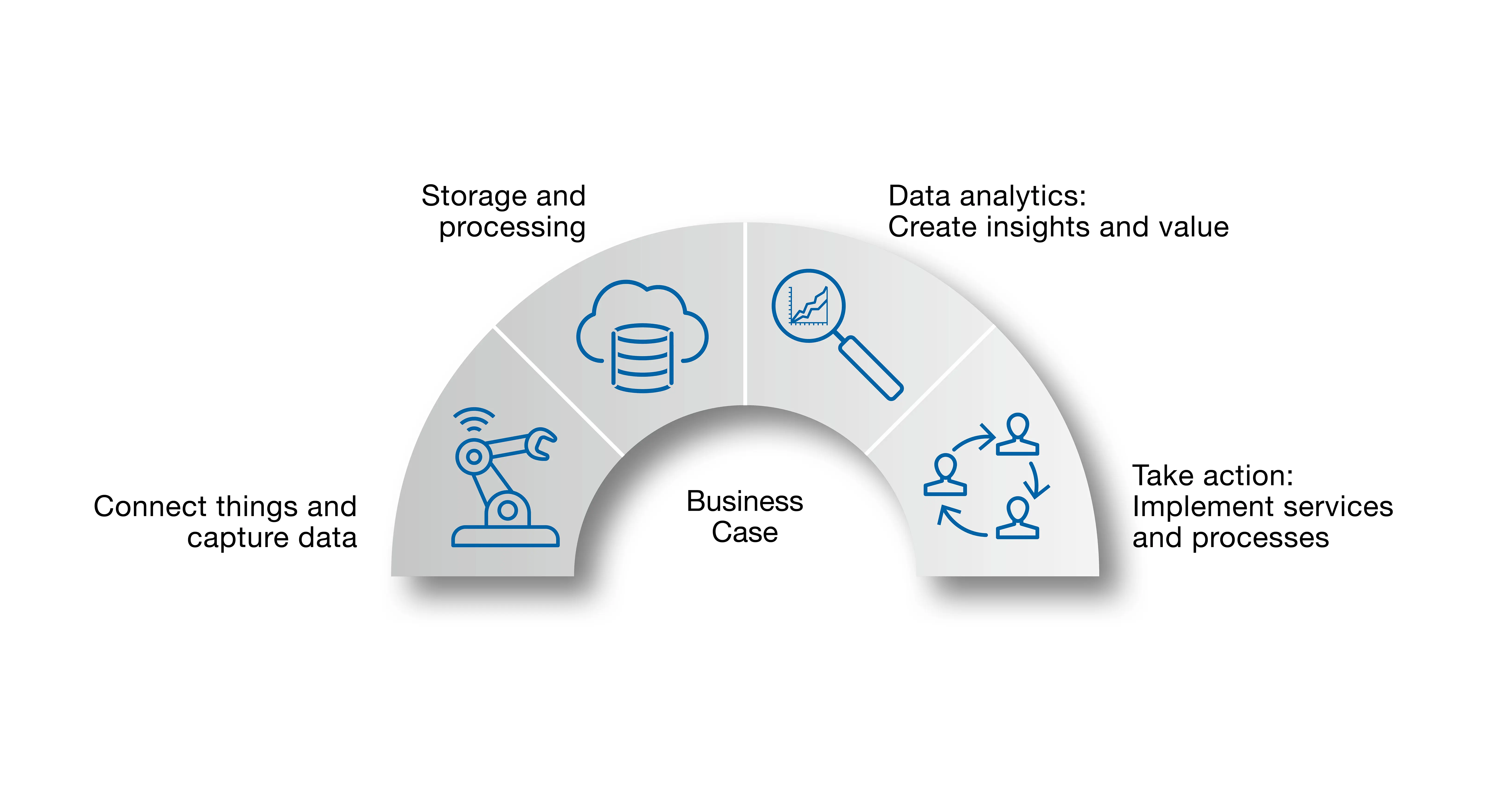

For the Internet of Things (IoT), ZHAW has expertise in wireless information transmission, such as low-power sensors and wireless communication, as well as in solving complex tasks in the field of automation. With research and teaching in the field of cloud computing, ZHAW contributes to not only mastering but also analyzing the large amounts of data generated. This, in turn, provides the ideal starting point for offering research and services in data analytics and risk management, whether for decision-making in business processes or creating additional customer benefits through data-driven services.

ZHAW combines all these elements with a holistic approach to process design and simulation to achieve data consistency in today's business environment and to cover the entire chain from suppliers to customers (supply chain management), including consideration of global industrial solutions. The interdisciplinary Industrie 4.0 platform at ZHAW offers a comprehensive point of contact for SMEs and large companies with questions about Industrie 4.0 and IoT, with its wealth of research focuses.

Continuing education (in german)

- MAS Industrie 4.0

- CAS Industrie 4.0 – von der Idee zur Umsetzung

- CAS Additive Fertigung

- CAS Lean Management für technische Fach- und Führungskräfte

- CAS Logistikmanagement

- CAS Predictive Maintenance

- CAS Smart Service Engineering (Data Product Design)

- CAS Product Innovation and Leadership for Engineers

- CAS Angewandte IT-Sicherheit

Events (in german)

2023 – Perspektiven mit Industrie 4.0

Digitale Ökosysteme

2022 – Perspektiven mit Industrie 4.0

Synergien und Chancen für die Kreislaufwirtschaft

2021 - Perspektiven mit Industrie 4.0

Digitale Zwillinge im praktischen Einsatz

2019 - Perspektiven mit Industrie 4.0

Produktionsprozesse in der digitalen Welt

2018 - Perspektiven mit Industrie 4.0

von smarten Produkten zu neuen Service-Modellen

Industrie 4.0 Blog

-

BLOG

Haben Sie Ihr Netzwerk segmentiert? Und heute schon ein Backup erstellt?

Blogautor: Thomas Herrmann Eindrucksvolle Vorträge und wertvolles Networking an der Cyber-Security Konferenz im Rahmen der Konferenzreihe “Perspektiven mit Industrie 4.0” Die ...

-

BLOG

AI-driven Decision Intelligence

Blogautor: Helmut Sedding 🌟 Join us in Switzerland for our “AI-driven Decision Intelligence” event 🌟 🔍 Discover how AI is revolutionizing operations for enhanced efficiency and sustainability. ...

-

BLOG

Reverse-Engineering – Aufwändiger als gedacht

[Autor: Daniel Schmid] 3D-Scanning stand am Anfang, um die Grundlage für eine universelle Stattelstützenklemme zu schaffen. Dabei arbeiteten drei Partner zusammen, so dass 26 Punktewolken von ...

Presentations, speeches and publications

- Virtuelle Fabrik, TechTalk 2016: Referat 1, Christoph Heitz (in German)

- From Sensor to Business Case: Prof. Andreas Rüst

- c2-Magazin, 2016, Extrusionswalze mit wireless IoT-Sensor : Prof. Roland Küng (in German) (PDF 1.19 MB)

- Video: Praxisbericht Industrie 4.0 (in German)

- Video: Industrie 4.0 in Produktion (in German)

- Video: Instandhaltung und Predictive Maintenance (in German)

- Video: Wireless Sensor Netzwerke für den industriellen Einsatz (in German)

- Video: Neue Geschäftsmodelle (in German)

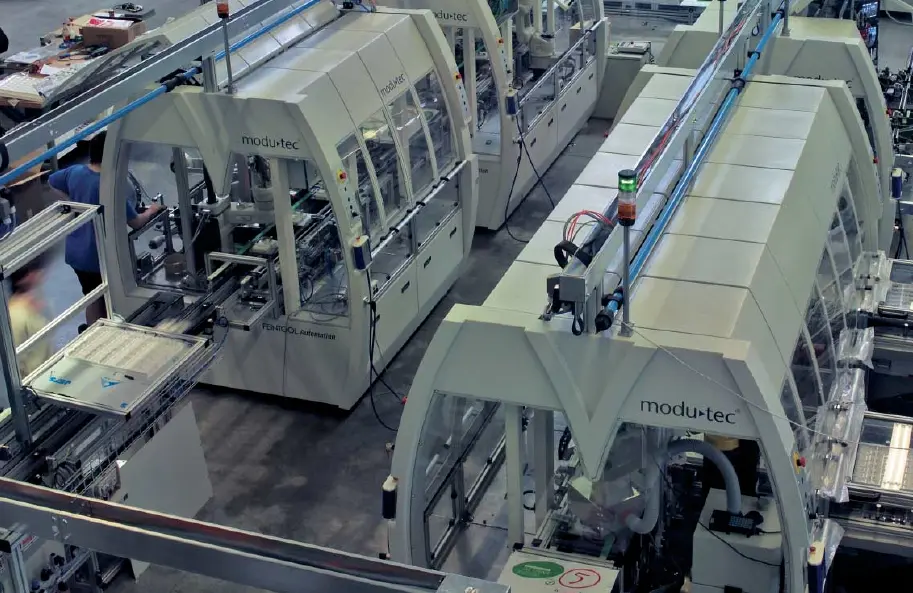

Industry 4.0 showroom

Our showroom provides an insight into our current Industry 4.0 research initiatives. A series of demonstrations showcases the ZHAW School of Engineering’s expertise in this field and the services it can offer. Interested? Then simply contact us to arrange a visit.

Research projects

Unfortunately, no list of projects can be displayed here at the moment. Until the list is available again, the project search on the ZHAW homepage can be used.

Project PRIME. Precisely calibrating output to match market demand

The costs of manufacturing in Europe are onerous, particularly for SMEs. Industry 4.0 applications have the potential to enable resources to be used more efficiently. Against this backdrop, the ZHAW School of Engineering worked as part of a European research consortium on the development of an intelligent production system. Read more