Robotics & Automation

The research area

Robotics and automation engineering enable the autonomous operation of machines and facilities. Thus, research in robotics and automation engineering helps reducing the negative impact that monotonous and health damaging tasks have on humans, and contributes to a reduction of energy consumption and an increase in cost effectiveness of industrial processes.

The focus of the robotics and automation engineering research area is on developing sophisticated applications that exceed today's industrial standard. In an interdisciplinary team, experienced and innovative engineers focus on developing tools for intuitive human-machine interaction that meet all necessary safety requirements. This allows for their research to be used not only in an industrial environment, but also in different areas of everyday life.

Focus of the research area

- Use of industrial robots in production and automation

- Assisting and service robots

- Autonomous systems

- Design and programming of (fail safe) controls and visualisations

- Control and regulation of electrical actuators with SPS

- Decentralised automation solutions and communication with different bus systems

Projects in Robotics & Automation

Milking robot for the Swiss market

Milking robots have been found in the stables of milk-producing agriculture for more than twenty years. They allow farmers to make their daily structure more flexible thanks to the support of the robots. Since the cows themselves go to the robot and are milked there fully automatically, the task of the modern farmer is limited to the control of the technology and the welfare of the animals.

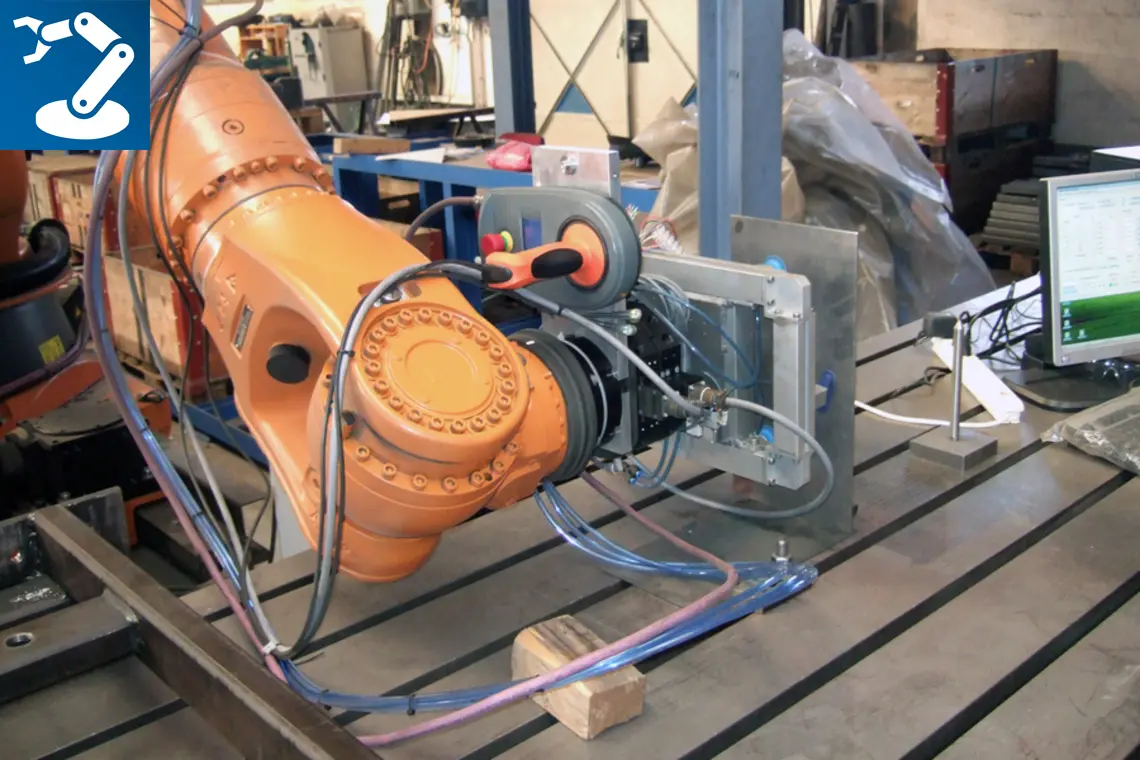

Automatic control cabinet wiring in a human-robot cooperation

Electrical control cabinets, for example for controlling larger machines or other technical systems, are usually very individually tailored to the specific intended use and are therefore only identical in small series. Today, these control cabinets are almost exclusively assembled and wired manually. Despite small series and sometimes high complexity of the task, there is a desire to be able to produce control cabinets as automatically as possible. The IMS has developed a robot system for this. More information about this project.

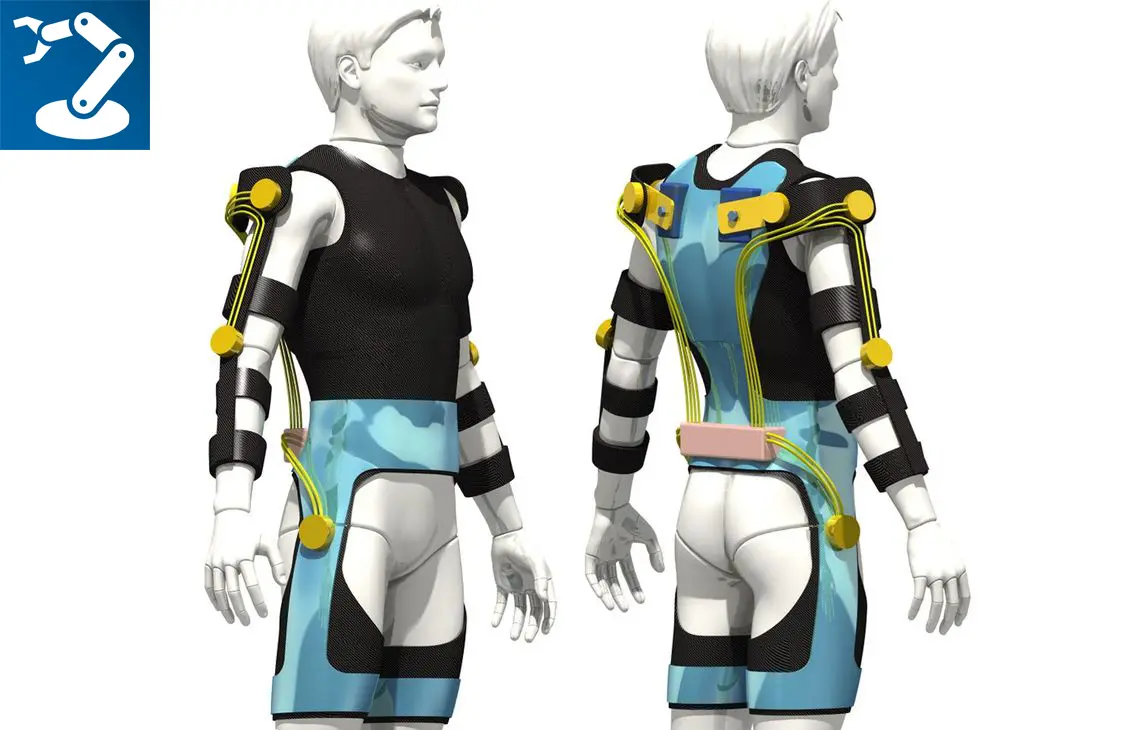

Robo-Mate: Intelligent, flexible exoskeleton

The goal of Robo-Mate is to develop a user-friendly intelligent cooperative light weight wearable human-robotic exoskeleton for manual handling work in order to reduce musculoskeletal diseases in industrial environments. More information

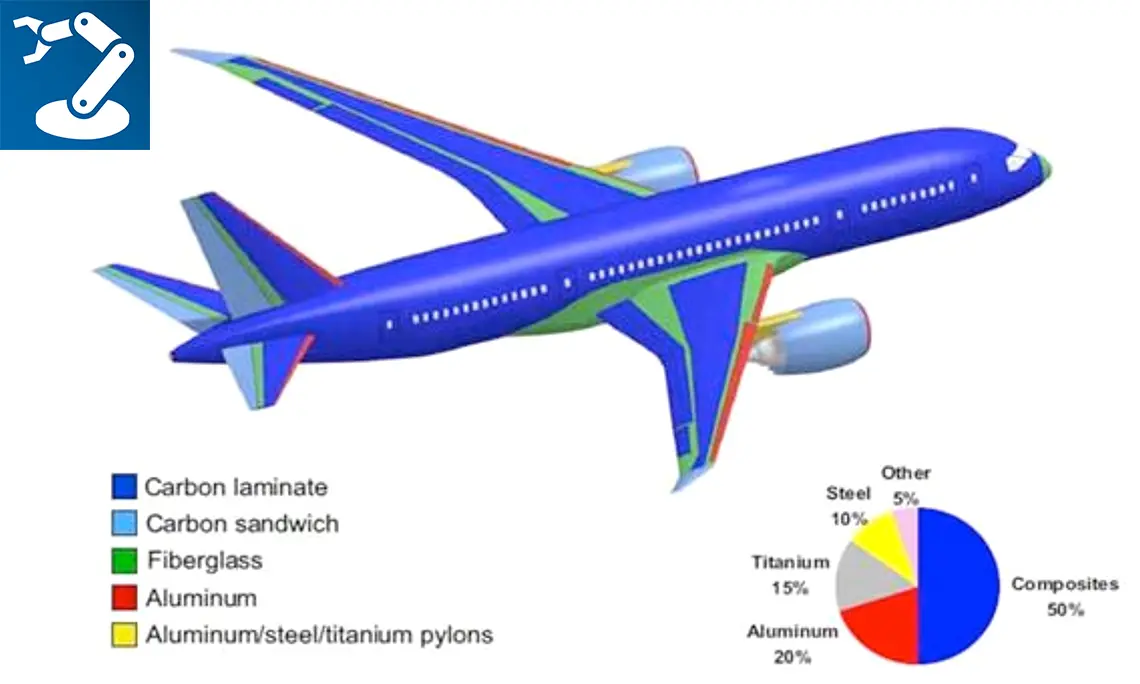

EcoStrippAir: Aircraft Surface Paint Removal System

The ECOSTIPPAIR project is developing an ecological aircraft maintenance system, which will be able to strip various painted/coated surfaces off planes efficiently and gently, without the use of chemicals. The process is up to 85% fully automated. In this way harsh working conditions, which could cause work-related diseases, are avoided over the long term and costly damage to the surface of the aeroplane are avoided. More information

ECHORD: Human-robot collaboration in airplane assembly

Within the framework of the European Project ECHORD, the experiment JILAS (Jig-Less Airplane Assembly in low volume production by enhanced human robot interaction) was performed at the IMS. The research about cooperation of human worker and industrial robot in an airplane fuselage components assembly task was at the core of the project. More information

ARFLEX: Open robot control concept

In the EU project ARFLEX (Adaptive Robots for Flexible Manufacturing Systems), the IMS supported its industry and research partners in the development of a new and open robot control concept. The aim of the new control concept was to simplify the integration of intelligent sensors in robot applications. More information

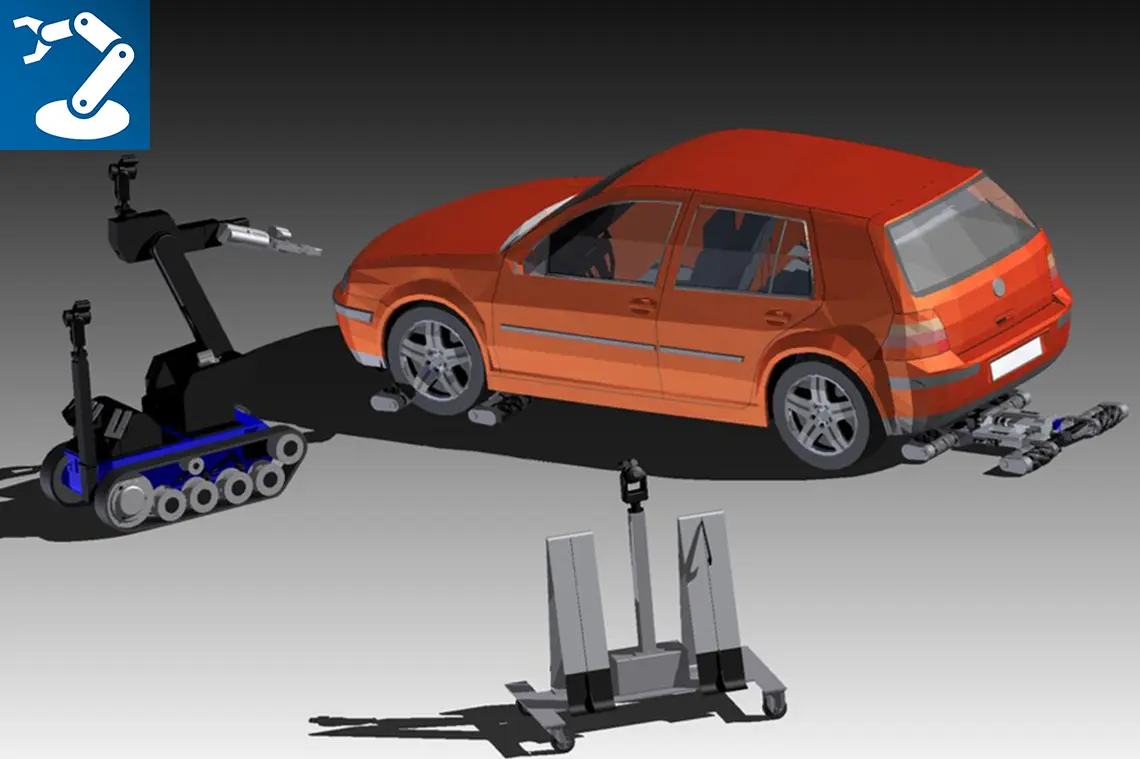

AVERT: Safe removal of suspect vehicles

The Autonomous Vehicle Emergency Recovery Tool (AVERT) provides a capability rapidly to deploy, extract and remove both blocking and suspect vehicles from vulnerable positions and confined spaces. More information

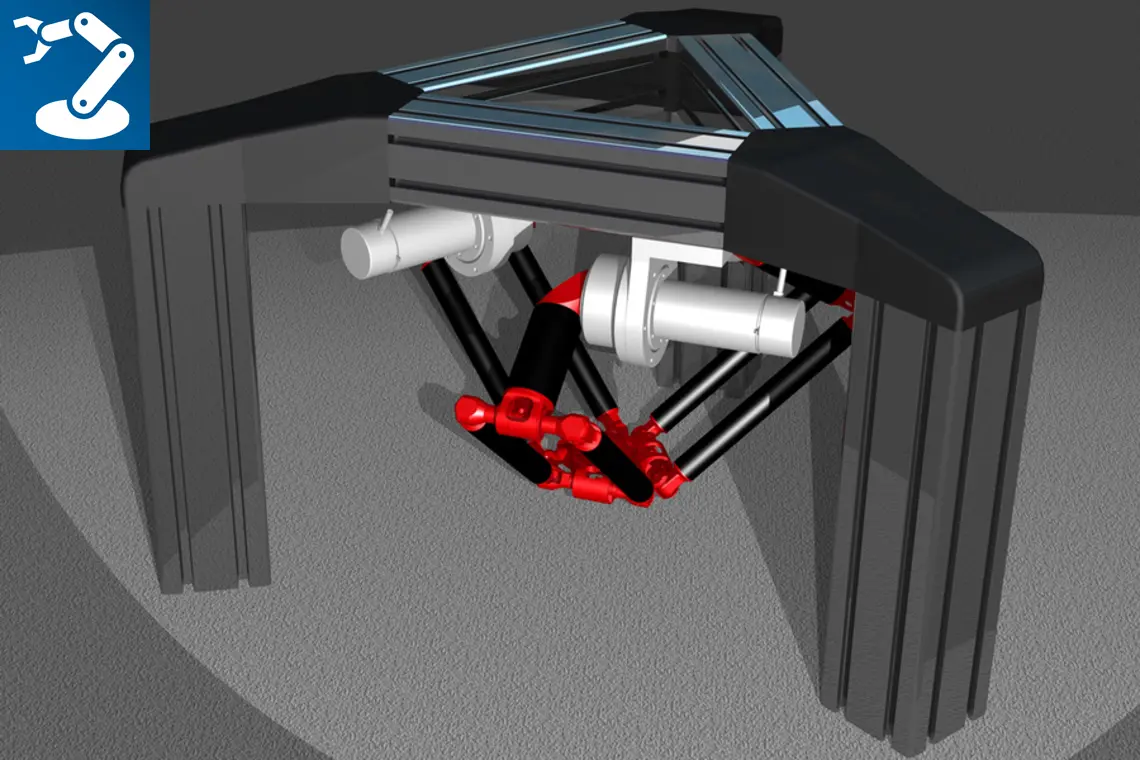

Micro Delta: Fast and highly precise robot system

The Micro Delta project aimed at developing a fast and highly precise robot system. The robot was designed to significantly outperform the precision and speed of current systems and to be cost-effective at the same time. More information

RAAS: Robot-based assistance system for welding processes

The robot assisted assembly system RAAS was developed to alleviate the assembly of parts that need to be welded together. In this system, the assistant robot grips and positions the parts that need to be connected, afterwards the welds are applied by an experienced welder. More information