With heat pump and induction: ZHAW researchers develop an efficient coffee machine

In an innovation project with the company Aequator, the ZHAW School of Engineering has developed an energy-efficient coffee machine. The special feature: the machine heats the coffee water in three steps. A combination of waste heat utilisation, heat pump and induction leads to maximum efficiency.

A thousand cups a year: that's how much coffee the average Swiss consumes. For a thousand cups of coffee, around 100 litres of water have to be heated from room temperature to almost 100 degrees. With the ten kilowatt hours of energy that have to be used for this, one could just as well do laundry ten times, work on a laptop for 500 hours or shave electrically every day for 76 years.

This shows that making coffee is not free. Coffee machine manufacturer Aequator from Arbon knows this. "The ecological aspect is becoming increasingly important in our sales markets," says Raoul Meyer, Head of Research at Aequator. "Since heating water is the biggest energy consumer in a coffee machine, we are looking for new solutions."

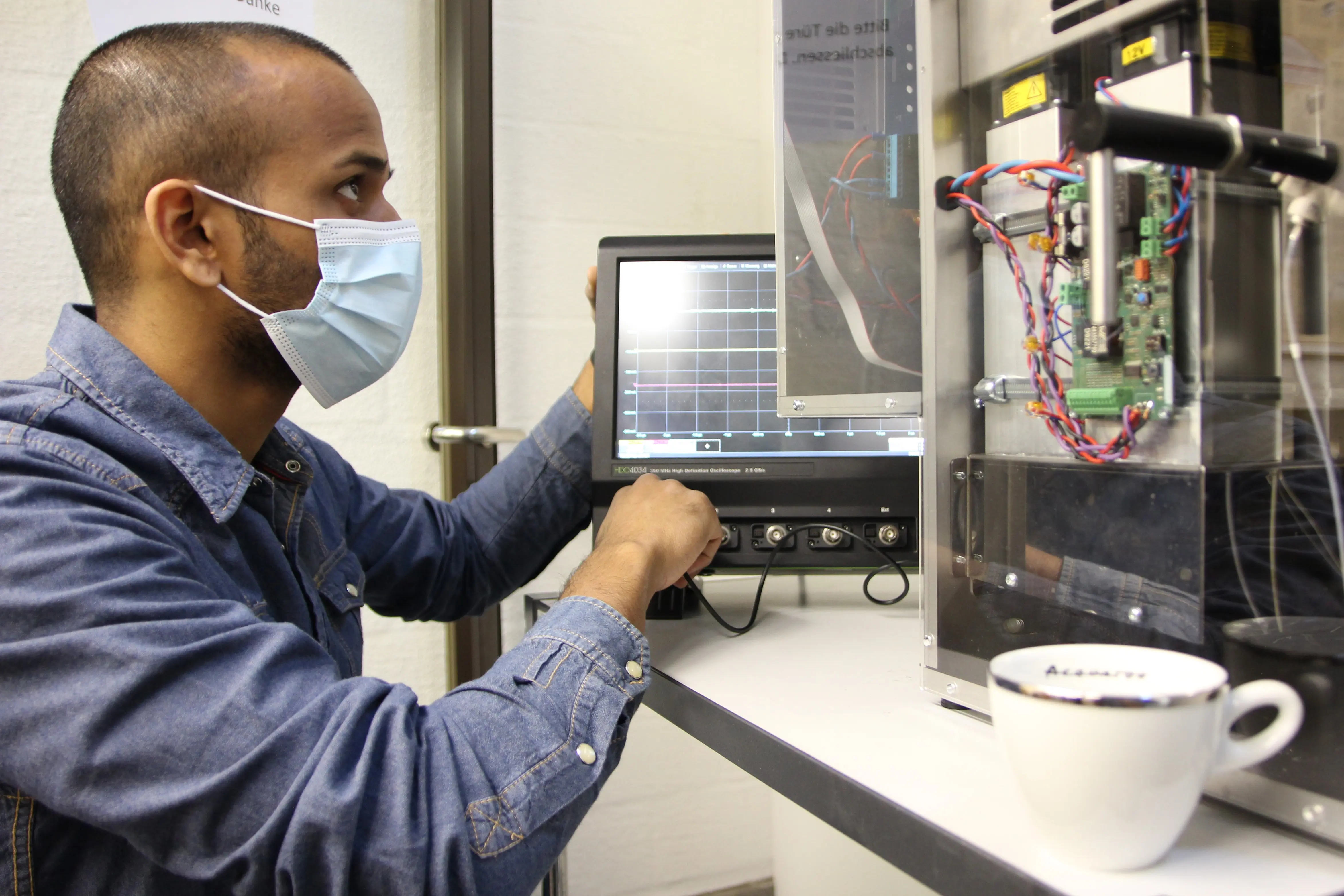

To make its machines more efficient, Aequator AG teamed up with the ZHAW Institute of Energy Systems and Fluid Engineering (IEFE) for three years. With financial support from Innosuisse, the two parties have jointly developed a prototype that is exceptional in several aspects.

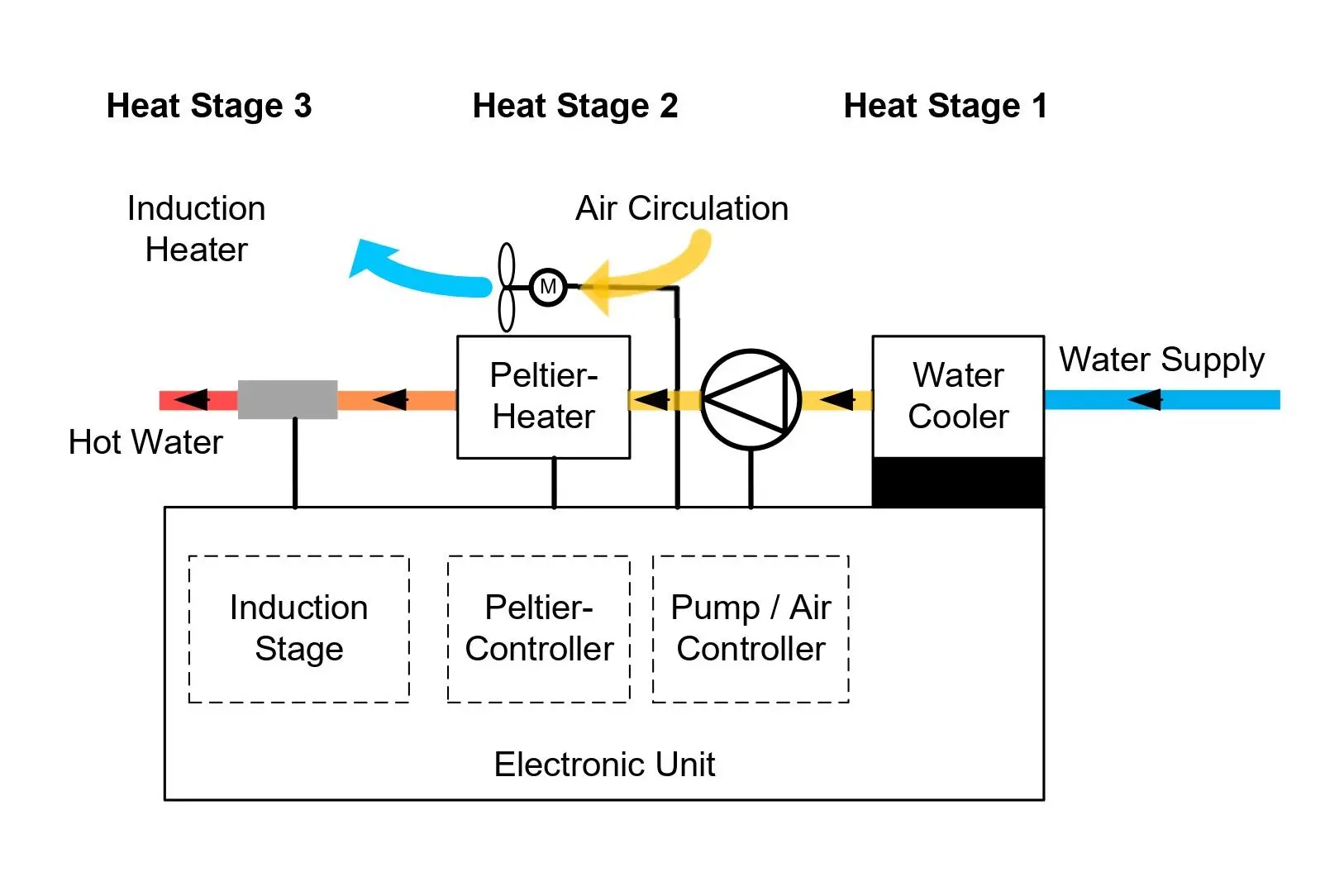

First waste heat, then heat pump and induction

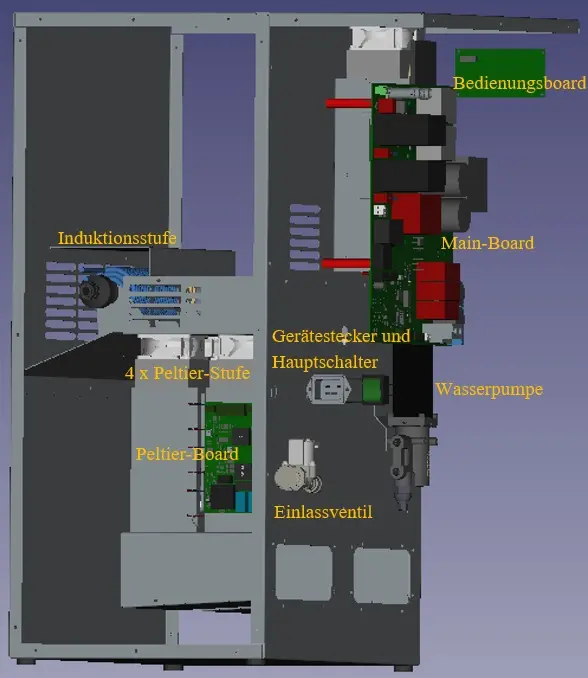

"Our prototype heats the coffee water in three steps," says Jimmy Oliapuram. As the project manager of the IEFE research group Electrical Storage Systems and Power Electronics, he was responsible for the development of the new coffee machine. The first of the three steps: The coffee machine heats the cold water with the loss energy of the electronics. Oliapuram says: "This optimizes the efficiency and at the same time allows the electronics unit to be cooled, thus increasing its service life."

The second step involves heating by means of Peltier elements, which function like a heat pump. A current flow in the Peltier element ensures that one side of the element cools down while the other heats up. The cool side is connected to the ambient air via a heat exchanger, while the warm side heats the coffee water to 40 degrees.

Because that is not enough, the Peltier stage is followed by an induction stage. "A cylindrical coil and a flow heater heat the coffee water to over 90 degrees," says Oliapuram. The way it works is exactly the same as any induction cooker, he says. "A high-frequency magnetic field heats a magnetizable material which gives off heat to the water."

There are good reasons for the complex structure

Heating water in a coffee machine with three different methods – couldn’t that be done in a simpler way? "Yes," says Jimmy Oliapuram, "but the efficiency would suffer. " For the Peltier stage, the IEFE and Aequator set a target of 200 % efficiency factor – and achieved it. "If we were to heat the water to more than 40 degrees, the efficiency would drop. At some point, the heat pump would be useless."

A coffee machine with induction only, that would be possible, Oliapuram admits. But the efficiency of the induction stage is only about 80 %. The combination of using waste heat, a Peltier heat pump and induction therefore achieves maximum efficiency – which in turn has several advantages.

"We strive for high efficiency not only to save energy," says Oliapuram. The higher it is, the faster the heating of the water works with a limited plug-in power of just under three kilowatts. This is particularly important for the Aequator machines, which are often found in open-plan offices or company canteens: "They stand still for hours, then all the employees have a break at the same time and want coffee. The machine has to heat as much water as possible in the shortest possible time." This is exactly what is achieved with induction in combination with Peltier elements.

The prototype is fast and economical

To determine how efficient the IEFE development really is, Jimmy Oliapuram took a measurement according to the EN 60661 standard. The result:

"Our machine ends up in energy efficiency class A++. That's as good as it gets for coffee machines."

Jimmy Oliapuram

The machine's second big advantage is its speed. "It heats the amount of water for a cup of coffee in 18 seconds – which shortens the waiting time."

In addition to a fast and energy-efficient prototype, the Innosuisse project has borne other fruit. "The project has highlighted the problems that still need to be solved," says Raoul Meyer from Aequator AG. "Next, the prototype will be installed in our test field and subjected to specific tests – we will focus our attention primarily on these still unsolved problems." There is indeed a lot to be clarified before the system is ready for series production, Meyer says, but: "We can already see individual points of detail in the implementation."

At a glance

The Innosuisse project 25875.1 PFIW-IW entitled "Energy-efficient heating system for coffee machines" can be found on Aramis, the federal administration's research database.

At the IEFE, in addition to Jimmy Oliapuram, Andreas Heinzelmann, Patrick Baumann, Manuel Räber, Andreas Schellenberg and Patrick Amiras were also involved in the coffee machine project.

Project partner: Aequator AG

Project duration: 2017 - 2020