Fiber-reinforced Composites

The laboratory of carbon composites is focused on the development of lightweight structures, their materials, manufacturing processes and testing.

Our main tasks are the development and characterization of components made of fibre-reinforced composites, based on design, manufacturing and testing requirements. This includes the production and testing of prototypes. An extensive and universally usable, modern infrastructure is available for this purpose.

Production and process simulation

At IMPE's Laboratory for Fibre Composites, our research focuses on developing innovative manufacturing processes complemented by advanced simulations of fibre-based materials. The lightweight solutions created by us offer an outstanding ratio between mechanical performance and weight, contributing to enhanced energy efficiency in modern high‑performance applications.

To advance established manufacturing techniques, such as the resource-efficient out-of-autoclave process, we are introducing robot-controlled technologies in the field of Advanced Manufacturing. These cutting-edge manufacturing methods and digital tools are distinguished by their precision and efficiency. Integrating these modern technologies helps to meet industry demands for adaptable production processes. By employing numerical simulations, particularly in textile forming and draping, we can accurately predict material behavior during production and optimize processing parameters with precision. These virtual methods contribute directly into the development and optimization of innovative lightweight structures, further enhancing the quality and reproducibility of fibre composite manufacturing.

Our research in bonding, joining, and sandwich technologies enables us to continually refine modern lightweight structures that meet the specific demands of fibre composites in the aerospace and automotive industries. We ensure high connection quality and material durability, with resistance to extreme conditions being designed, tested, and validated at IMPE.

Our objective is to generate new insights through experimental research and the development of simulation models, ultimately improving the manufacturing processes for highly complex fibre composite components. We work closely with industrial partners and other research institutions to continually expand our expertise and translate it into practical, real-world solutions.he further development of simulation models and material testing methodologies for advanced material and structural analysis.

Material testing and structural simulation

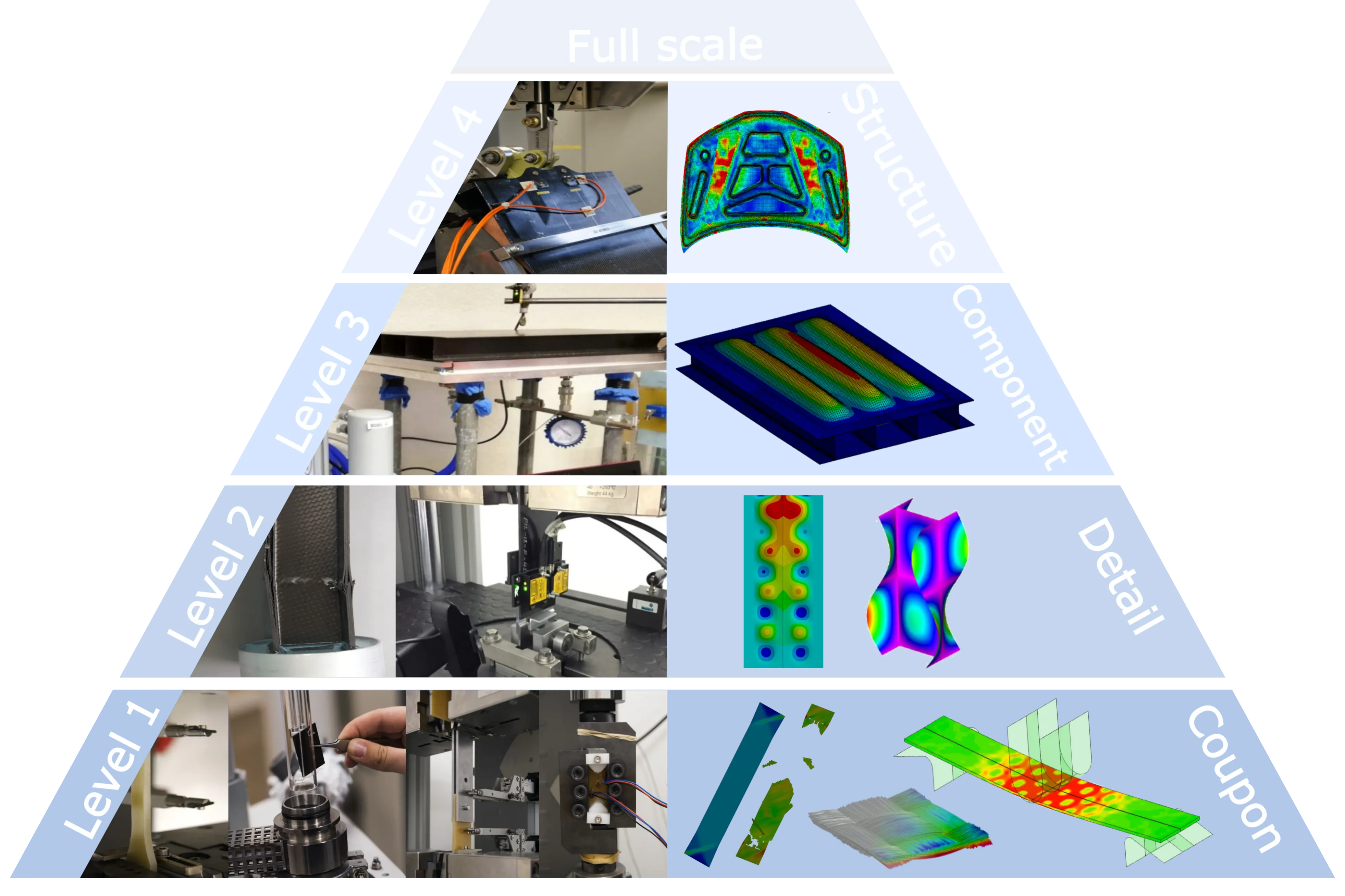

Our fibre composite laboratory provides comprehensive material testing of fibre-based materials in accordance with national and international standards, enabling the investigation of mechanical behaviour under real-world load and environmental conditions. In close collaboration with numerical structural simulations, we examine fibre composites using the building block approach, ranging from coupon specimens to complex structures subjected to diverse loading conditions.

By integrating experimentally supported virtual simulations throughout the entire development cycle of high-performance fibre composites, we gain deep insights into both material and component performance. This holistic approach allows us to analyze and optimize material behavior early in the development process. The seamless integration of experimental testing with virtual simulations shortens development timelines and enhances the overall efficiency of the process. Rigorous material testing provides the foundation for creating accurate material cards for numerical simulations. Combining complex experimental tests with virtual simulations enables us to evaluate and characterize the mechanical properties of intricate components with minimal trial-and-error, facilitating the design of lightweight structures with enhanced performance potential.

We place a strong emphasis on the sustainability of fibre composites and their lightweight structures. Through fatigue testing of fibre composites and their joints, we develop methods to prevent material failures and extend the service life of components. The findings from our research directly inform the further development of simulation models and material testing methodologies for advanced material and structural analysis.in.

Applications

Our fibre composite laboratory provides customized solutions for a wide array of high-tech applications across multiple industries, with a particular emphasis on the aviation and space sectors. The technologies and research advancements developed at our institute are applied to cutting-edge projects, especially in aerospace. Together with our industry and research partners, we explore innovative lightweight design concepts based on fibre composites.

A key area of focus in our research is lightweight structural design, where we investigate methods to reduce weight while preserving structural integrity. Specifically for the aviation industry, we are developing a novel robot-assisted winding process for load-path-optimized, waste-free production of high-performance composite structures. This approach addresses the growing efficiency and performance demands of the aviation sector.

We are also deeply engaged in developing structural repair and maintenance solutions for aviation components subjected to cyclical loading. Our research contributes to creating efficient repair techniques that restore damaged composite components, thus enhancing the sustainability and cost-effectiveness of fibre composite structures throughout their lifecycle.

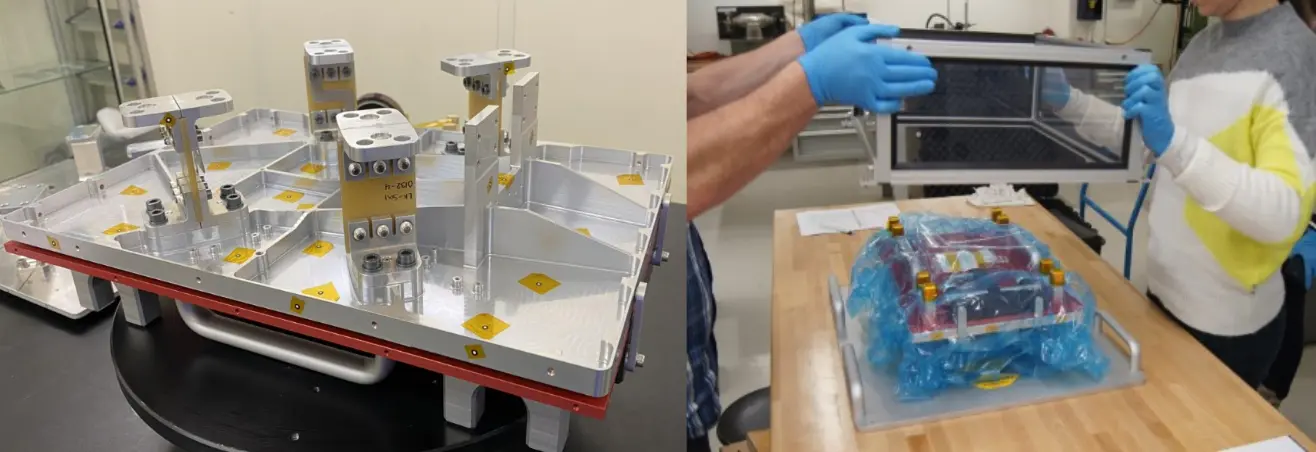

In addition, our work on optical benches and thermally stable structures is yielding new insights into the use of these materials in high-precision applications, particularly in satellite construction. By applying advanced dilatometry methods, we analyze and validate space structures, ensuring the reliable operation of high-precision instruments in institutional space exploration.

Our service portfolio is further enriched by active participation in innovative research and implementation projects. Close collaboration with research institutions and industrial partners allows us to stay at the forefront of technological advancement and swiftly apply new discoveries. Through this, we continually contribute to the improvement and further development of fibre composite technology, ensuring it meets the future's evolving requirements.