Efficient cooling units thanks to mobile measurement

A cooling unit can only be energy-efficient when its is known, exactly which loads it is actually exposed to. Optimisation therefore starts with a metrological challenge. The «Mobile Chiller Analyzer» can manage this. It was developed at the Institute of Energy Systems and Fluid Engineering in line with this master's thesis.

Refrigeration Challenge

To prevent food from spoiling it must be stored in stable climatic conditions. A wholesaler's cold room must therefore continuously be at the same indoor temperature so that meat or produce keep a long time. The cooling unit, which maintains the correct temperature inside a warehouse must therefore be very efficient: When a cold room is stocked with new goods, everything must be chilled as quickly as possible – current stock must not warm up. Even if the outdoor temperature rises, it's important to keep the temperature inside the cold room steady.

Energy use as a planning problem

A cooling unit is designed and built for reliable performance. How much energy is needed is only a secondary consideration. The design is therefore always on the absolute safe side and considers maximum machine utilisation. In reality, however, this range of capacity is rarely utilised. Therefore machines which do not operate within their efficient and optimal range of capacity are primarily used. They consume more energy than necessary.

Metrological solution

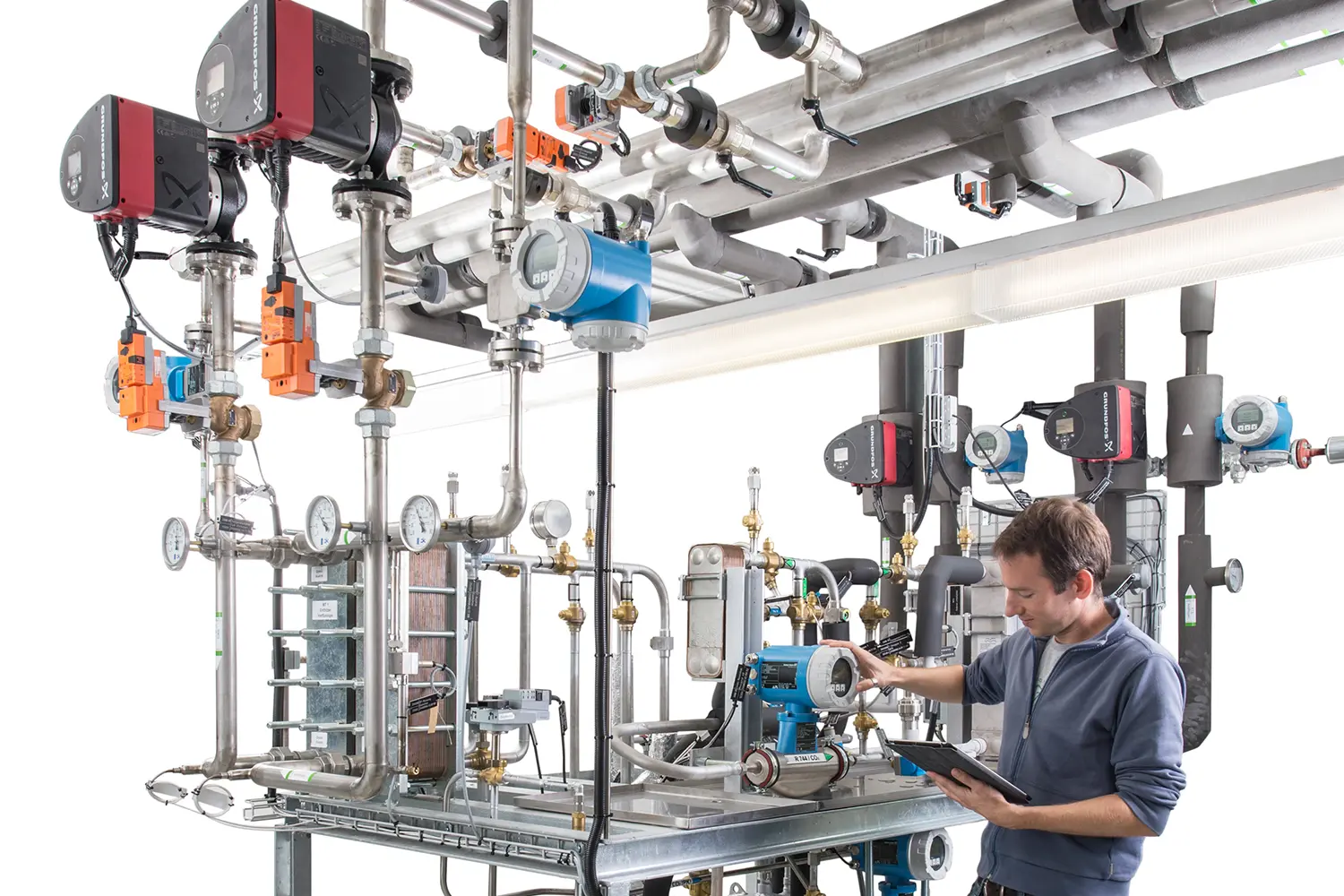

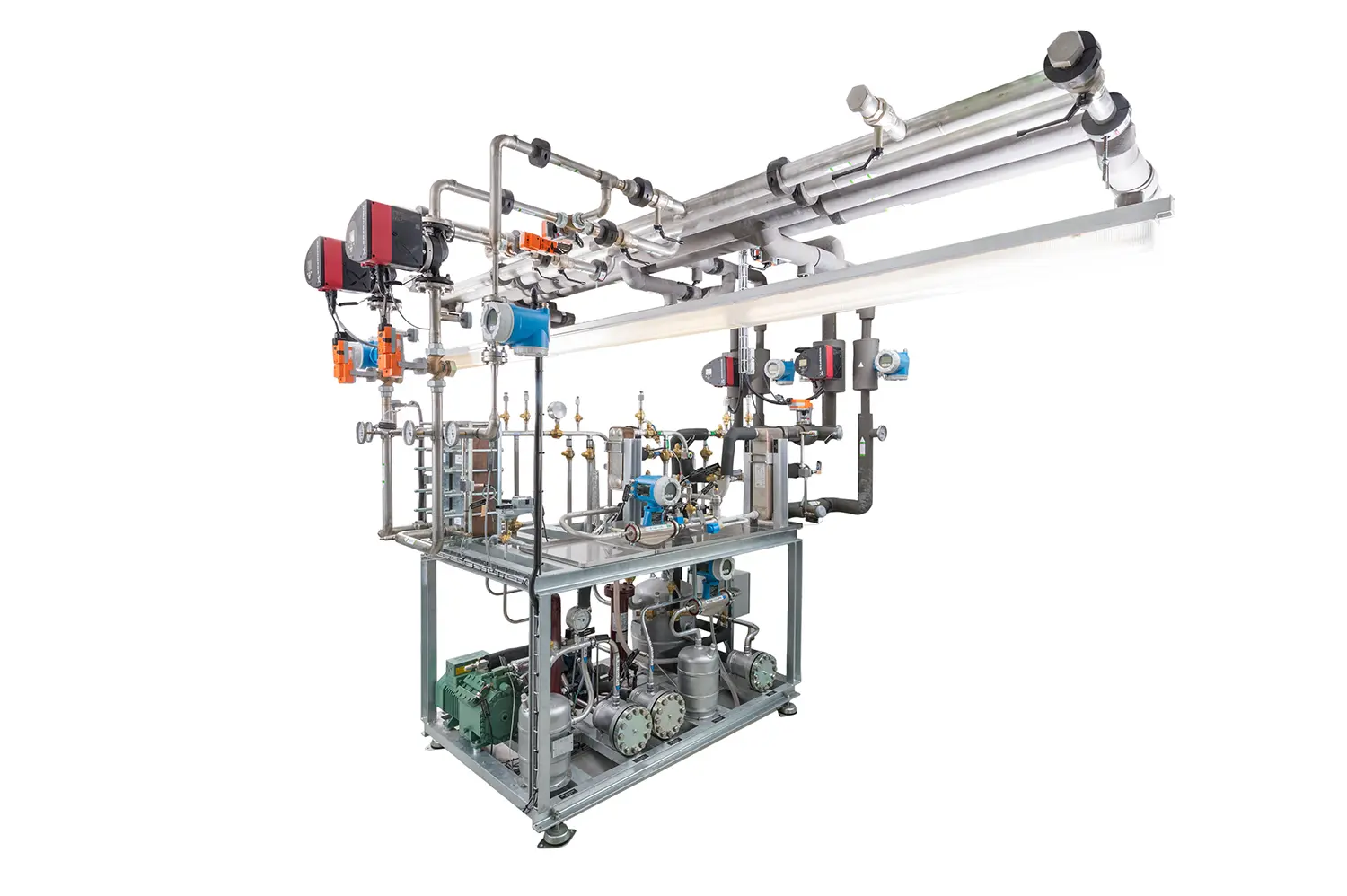

Development work on energy-efficient cooling was done at the Institute of Energy Systems and Fluid Engineering (IEFE) in line with a master's thesis. The result is a mobile measuring instrument and the related software. The device can be connected to any chiller to measure its actual utilisation. This data can then be used to determine and assess the performance indicators for various load scenarios and the energy efficiency rate. The co-developed data collection software allows for quick, easy and partly automated preparation of measurements. After the measurement the specific operating and design recommendations can be devised. This enables more economical and more energy-efficient cooling unit design or operation without having to accept cooling risks.

Mathias Lindt obtained his title as Master of Science in Engineering (MSE) with his master's thesis «Developing an instrument to determine the partial load performance of cooling units». He was advised at the Institute of Energy Systems and Fluid Engineering in the core area of energy efficiency.

Advisor: Frank Tillenkamp