Research area: Product Development

Our Product Development research area focuses on the development of innovative solutions and products via research, design and implementation. We start by understanding the problem and defining the business case and then develop the technical solution until it is ready for series production. Our team designs, calculates and creates test facilities and test benches.

Our services include:

- Machine and product development

- Transmission and drive technology

- Design and development of machine elements

- Structural optimisation / topology optimisation

- Simulation-supported product development

- Development of experimental designs

- Construction and operation of service life test benches

- Target costing

- Agile development methodology

The sub-competencies Machines, Simulation and GearLab enable us to develop complex solutions for different application areas. In addition to creative approaches, construction and product design, our competencies also include agile product development, the use of fast prototyping for rapid testing of ideas, FEM calculation, the analytical and numerical design of machine elements as well as functional and endurance testing.

Machines

Within the Machines sub-competency of the Product Development research area, we develop specific products and systems for use in industry as well as end consumer products. We implement ideas, from the first hand sketch through to CAD engineering, ergonomic studies, prototype setups and tests, all the way to readiness for series production.

Simulation

Simulation during development, which also includes the collection of data from tests to optimise the simulation, is an important part of successful product development. Simulation tools aid in the creation of solutions, especially for production plants that must operate with particular speed or precision. For the purposes of simulation, the IPP uses in particular Abaqus and ANSYS for FEM calculation, TOSCA for structural optimisation and KISSsys for gear calculation. Depending on the requirements, additional software from the field of 3DExperience and software for simulating different manufacturing processes (sheet metal bending, injection moulding, casting, CAD/CAM simulation) is also used.

Gear Lab

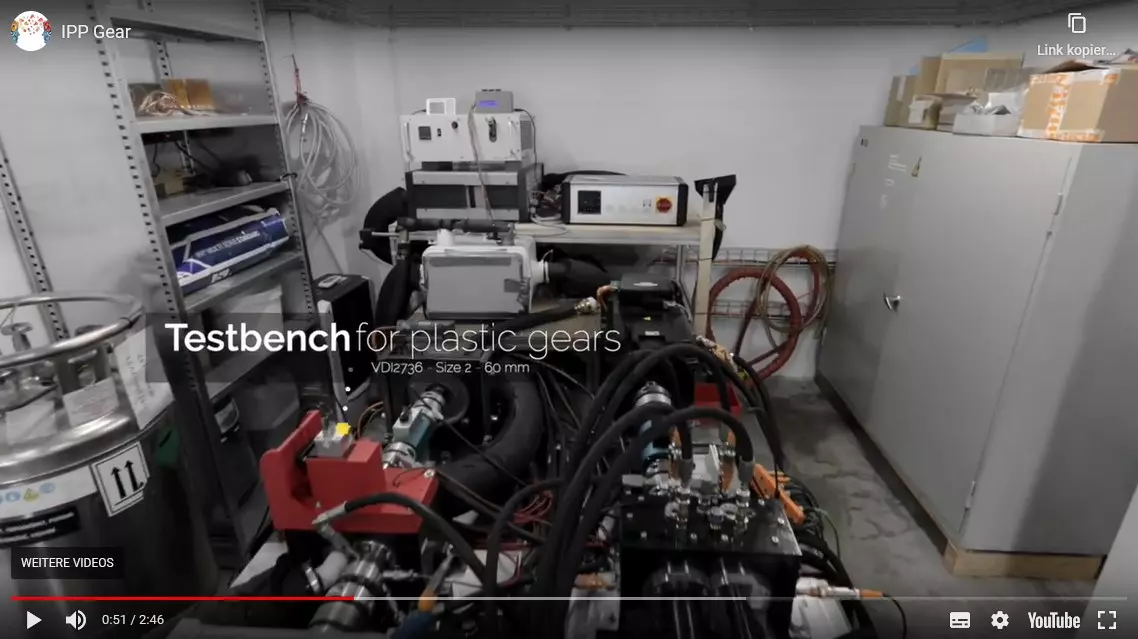

In recent years, the gear technology working group at IPP has developed into an important partner in the national and international industrial and academic landscape. We preside over in-depth knowledge in the design of steel and plastic gears. Modern test benches, manufacturing and measuring machines as well as the appropriate calculation programs are available for carrying out research and service projects.

The IPP team can offer the following research skills:

- Development of customised test benches

- Design of gears with KISSsoft and complete drives with KISSsys

- Creation of KISSsoft material data

- FEM calculations with ANSYS, structural optimisation of the gearwheel body with TOSCA

- Production of spur and bevel gears with EUKLID

- Gear tests

- Measurement of gearwheels (two-flank rolling test, tooth width measurement, imaging/tactile measurement)

- Lubricant tests with FZG-A and FZG-C gearing.

- Analysis of damage types, metallurgical investigations, tests according to VDI 2736

Contact

Please get in touch if you would like to discuss your project ideas with us.

Dr. Hans-Jörg Dennig, Head of the Product Development research area, Prof. Adrian Fassbind, contact for Machine and Plant Development, Frank Huber, contact for Simulation and Target Costing und Stephan Koll, contact for Agile Development Methods, will be happy to help.

Platform

Reference projects

- Science Toys - Science Tools

- Vision control systems for PO&QS

- CleanLE2: Demonstration of a Decontamination Device Prototype for Business Jets and Experimental Validation

- Cross-linked paper: Wirelessly networked, electronic signage based on e-paper

- Ceramic injection moulding of dental implants with osseo-functional surface

- TOP GEAR - Industrial production of gears based on thermoplastic high-performance fibre composites