Lower risk of infection thanks to ZHAW prototype

A team at the Zurich University of Applied Sciences (ZHAW) developed a prototype of a more flexible supply line for mechanical circulatory support devices. This reduces the strain on the skin and thereby lowers the risk of bacteria entering the body and causing infections.

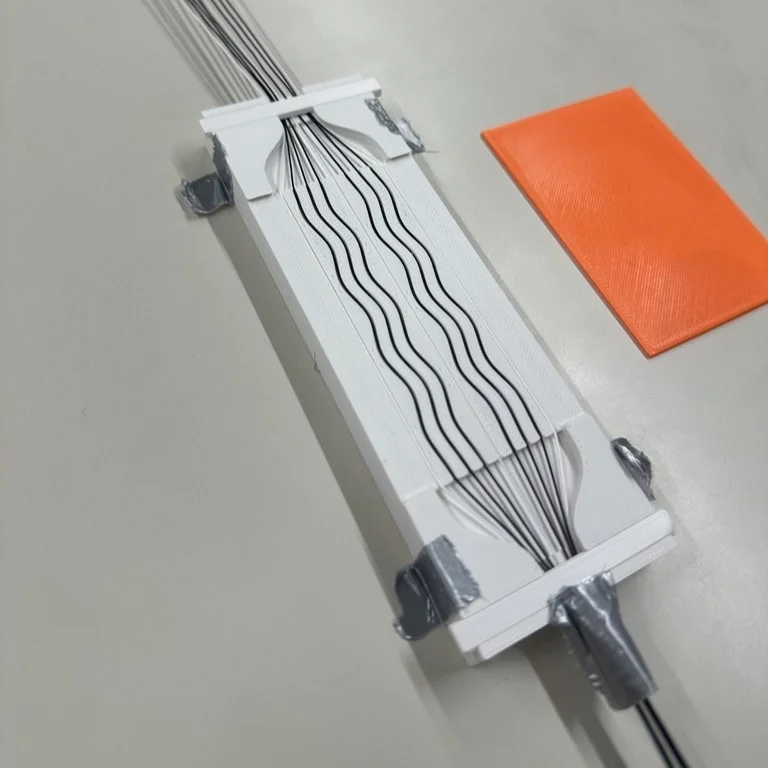

In the project Conductive Skin, the team for Sensors and Measuring Systems at the ZHAW Institute of Computational Physics (ICP) developed the prototype of an ultra-thin and flexible supply line, a so-called driveline, for supporting mechanical circulatory support devices (MCS). These implanted systems offer people affected by heart failure an alternative to heart transplantation, which is often not available due to a shortage of donor organs.

However, these MCS have a weak point: the pump inside the body must be controlled and supplied with energy from the outside. This is done with a driveline that passes through the skin. Conventional drivelines are rigid and exert constant tension on the skin at the exit site. This delays wound healing and provides a point of entry for bacteria. Possible infections can result, which can be very dangerous for patients.

Reduced wound size = reduced infection rate

To counteract this, Conductive Skin investigated the use of alternative ultra-thin and flexible drivelines. The prototype developed by ZHAW consists of several thin strands instead of one large line. A smaller cut is necessary to implant the driveline into the body. This reduces the overall size of the entry point through the skin and at the same time increases the flexibility of the driveline. The investigations showed that the prototype works flawlessly. The skin healed faster compared to conventional drivelines, and the number of bacteria proved to be much lower. The risk of infections is therefore reduced.

Optimization of the prototype

The results of the Conductive Skin project were recently published in The Journal of Heart and Lung Transplantation by ScienceDirect. Based on the successful study, the prototype developed by ZHAW is now being further improved by two students from the Northeastern University in Boston. The goal is to found a new start-up company to take over the prototype.