Additive Manufacturing of Nickel-based Superalloys with Laser Beam Shaping

The market share of the industrial partner for additive manufacturing of Nickel-based superalloys is to be increased. The technology of laser powder bed fusion (LPBF) will be significantly advanced beyond the state of the art to substantially enhance productivity.

Description

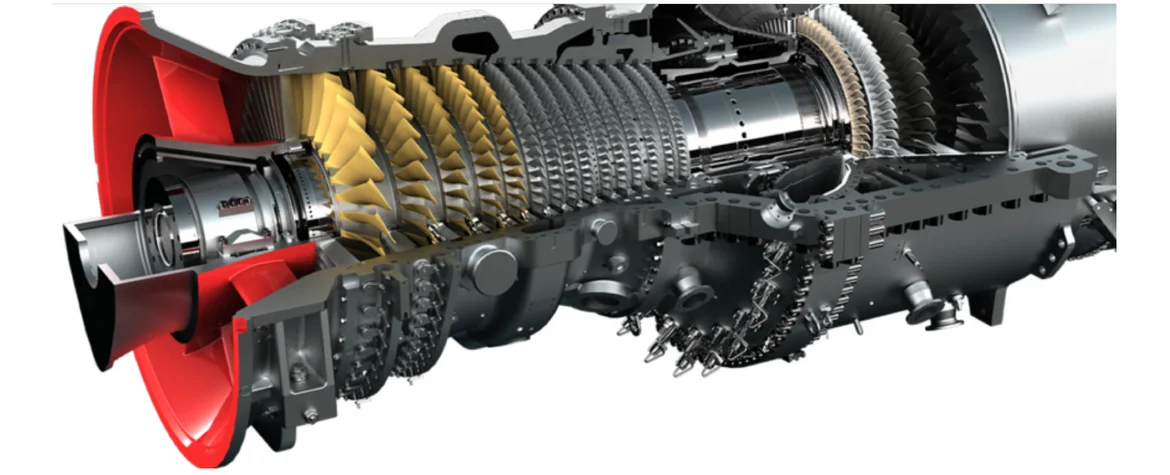

Nickel-based superalloys are used in modern stationary gas turbines as well as in aircraft engines. To make alloys with high precipitate contents suitable for the LPBF process, the entire process chain is being developed — from powder qualification and the LPBF process through to heat treatments. To increase the productivity of the LPBF process, laser beam shaping is employed.

Key data

Projectlead

Project team

Project partners

LINCOTEK RUBBIANO

Project status

ongoing, started 12/2025

Institute/Centre

Institute of Materials and Process Engineering (IMPE)

Funding partner

Innosuisse Innovationsprojekt

Project budget

456'924 CHF