Saving Energy through Digitalisation

In their bachelor's thesis, two ZHAW students developed a practical consulting tool and, through data analysis, identified energy-saving potential for industrial companies. The interdisciplinary collaboration between data science and energy and environmental engineering led to excellent results.

Industrial companies are under increasing pressure to reduce their energy consumption and CO₂ emissions. The advancing digitalisation presents opportunities that an interdisciplinary ZHAW team has investigated and prepared for practical application. According to Prof. Dr. Armin Eberle (ZHAW/INE) and Pascal Kienast (INE/Clemap), supervisors of the thesis, significant energy savings can be achieved through real-time monitoring, intelligent control, and data-based optimisation of industrial processes.

Students Lars Schneckenburger and Christian Zwicky from the School of Engineering, in collaboration with the industry partner Weisskopf Partner GmbH, developed a practical digital consulting tool called "DigitalCheck Industrie". This tool assesses a company's digitalisation level and provides initial recommendations for optimisation. The Excel-based tool consists of a modular questionnaire covering various industrial processes. In addition, the students conducted a data-based analysis of the energy data from the industry partner Courvoisier-Gassmann AG to identify and quantify specific energy-saving potential.

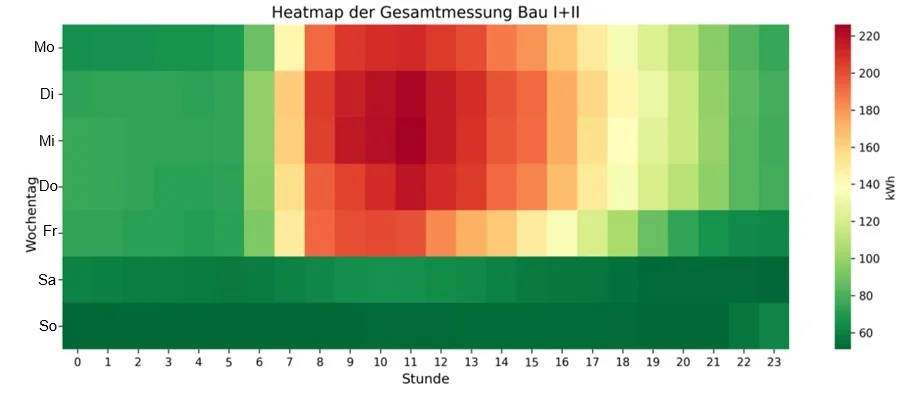

For example, demand-oriented control and night-time shutdown of ventilation/heating can save approximately 66 MWh of electricity per year. A small household consumes around 3 MWh per year, meaning that the optimisations can save the annual energy consumption of around 22 households.

If, for instance, energy is consumed at night when a company is closed and not producing, it is worth taking a closer look. "Digitalisation can increase energy efficiency in many companies. The ZHAW tool brings significant added value in practice through simple potential assessment. We will use it in our future consultations," says Stefan Eggimann, Weisskopf Partner GmbH, the client of the thesis. The consulting tool enables an initial diagnosis. Combined with detailed data collection and analysis, it is possible to accurately assess where efficiency potential lies.

"As a printing company, we rely on energy every day. Thanks to Clemap's energy measurement devices and the ZHAW's evaluations, we were able to develop exciting results that we are internally reviewing for implementation. These findings are of great importance to sustainably reduce our energy costs without affecting our printing processes." - Sylvain Villars, Production Manager, Courvoisier-Gassmann AG

Contact for project inquiries

Armin Eberle, ZHAW School of Engineering

Tel: +41 58 934 76 69

E-Mail: armin.eberle@zhaw.ch