New method for industrial process control developed

How to go from mere process monitoring to full process control with real-world, industrial applications of AI? With world models, shows a recent collaboration with Kistler Group.

We teamed up with the Kistler Innovation Lab a while ago to analyse the potential of AI in injection molding processes. The goal was to use machine learning on pressure sensor signals within the mold to learn when the quality of the produced parts deteriorates. Plastic materials specialists told us it is impossible. Nine month later we had a viable process monitoring model (see here and here, fruits of project DISTRAL).

But how to do the next step when bad process quality is detected – that is, change the machine parameters such that the process output returns to normal? This turned out to be a trickier one: While we very quickly able to tell in which direction one of a handful of parameters needed to be changed, it turned out to be hard to determine exactly which parameter. How could we make our model more aware of the physical causes and effects that effected our production process?

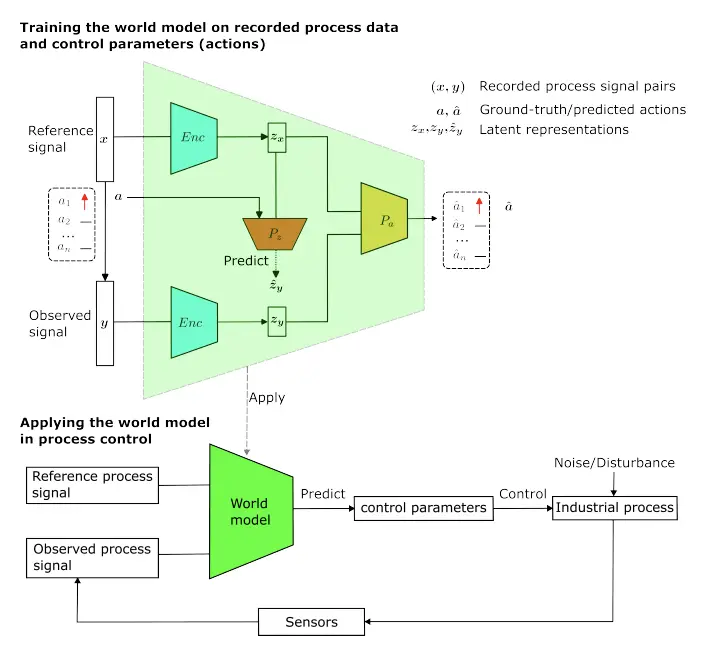

With a world model! World models recently became famous again in machine learning as ways to learn cause-effect relationships from data, to give machines a way to intuitively forecast future states based on actions taken - or, put more bluntly, impart some sense of "common sense" to them.

In a recent study spearheaded by PhD student Peng Yan that will be published at the IEEE Swiss Conference on Data Science, we were able to show that a relatively simple world model architecture trained on pairs of pressure curves together with the difference in their machine parameters as actions helps to build a model capable of process control of plastic injection molding. It does so by effectively disentangling said parameters and beats our older, autoencoder-based approaches decidedly. The model is inspired by the JEPA architecture but deviates from published versions in being directly actionable. We hypothesize that similar architectures and setups can be successfully used in a wider array of similar applications.