Additively manufactured components for cryogenic applications

Description

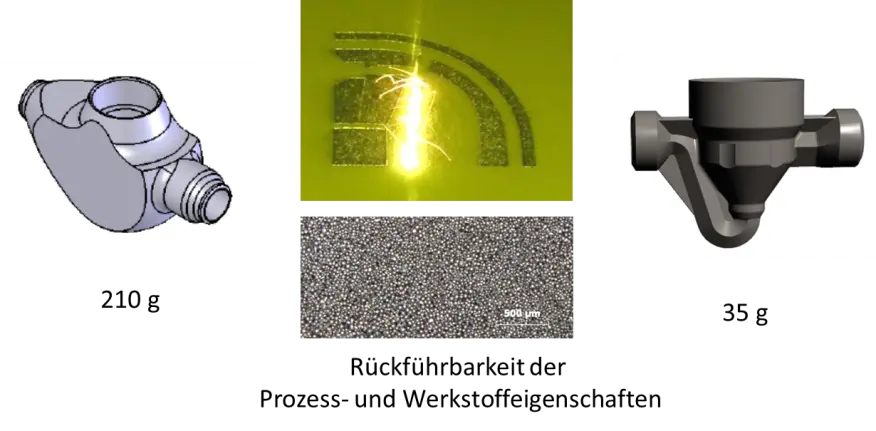

Feasibility study for the additive production of components for use at temperatures up to 4°K.Control and piping systems in cryogenics (sometimes at < 4°K) should have as little mass as possible in order not to slow down possible temperature change processes (cooling/heating up) or to avoid unnecessary additional cooling at constant process states.Due to the layered structure of the valve housing using additive manufacturing (selective laser melting (SLM) of stainless steel, 1.4404), a valve housing with very low mass can be manufactured with an optimum energy balance for use at very low temperatures.In addition to compressive strength and tightness, the components used at very low temperatures have to meet special requirements with regard to the materials and manufacturing processes used. If sufficient standardized standards, guidelines and test procedures for the materials and manufacturing processes used are available for conventional manufacturing processes, these standards are largely lacking for selective laser melting. In the VDI, DIN, ASTM and ISO there are efforts to close this gap.Starting from the basics of additive manufacturing, the project will present the advantages of selective laser melting on the basis of practical examples in the development and manufacture of components for cryogenics with special consideration of the necessary traceability (acceptance, standardization, duty of proof) of the material and process properties

Key data

Projectlead

Dr. Andreas Kirchheim

Deputy Projectlead

Livia Zumofen

Project status

completed, 08/2015 - 12/2015

Institute/Centre

Institute of Product Development and Production Technologies (IPP)

Funding partner

Innosuisse