Upgrade for 3D printer saves time and support material

ZHAW researchers have developed a new 3D printing process that is able to produce any shape without additional support material. The print head is tilted and rotates around its own axis. Conventional 3D printers could be upgraded with it.

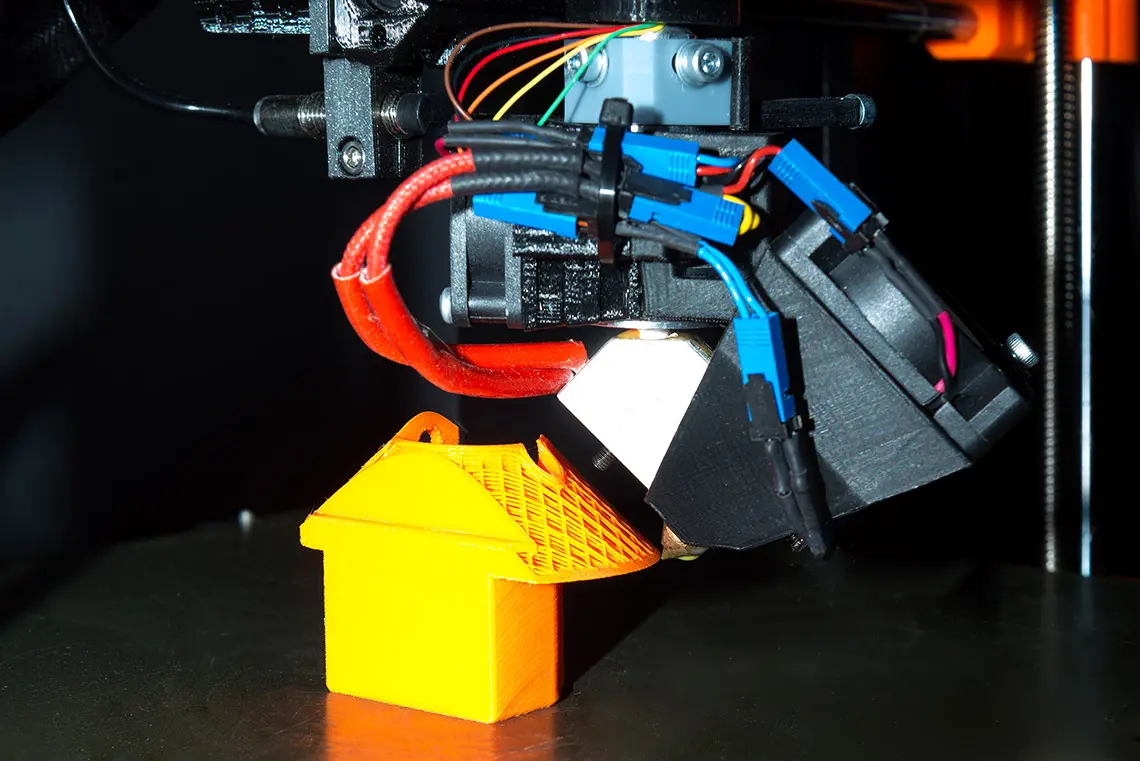

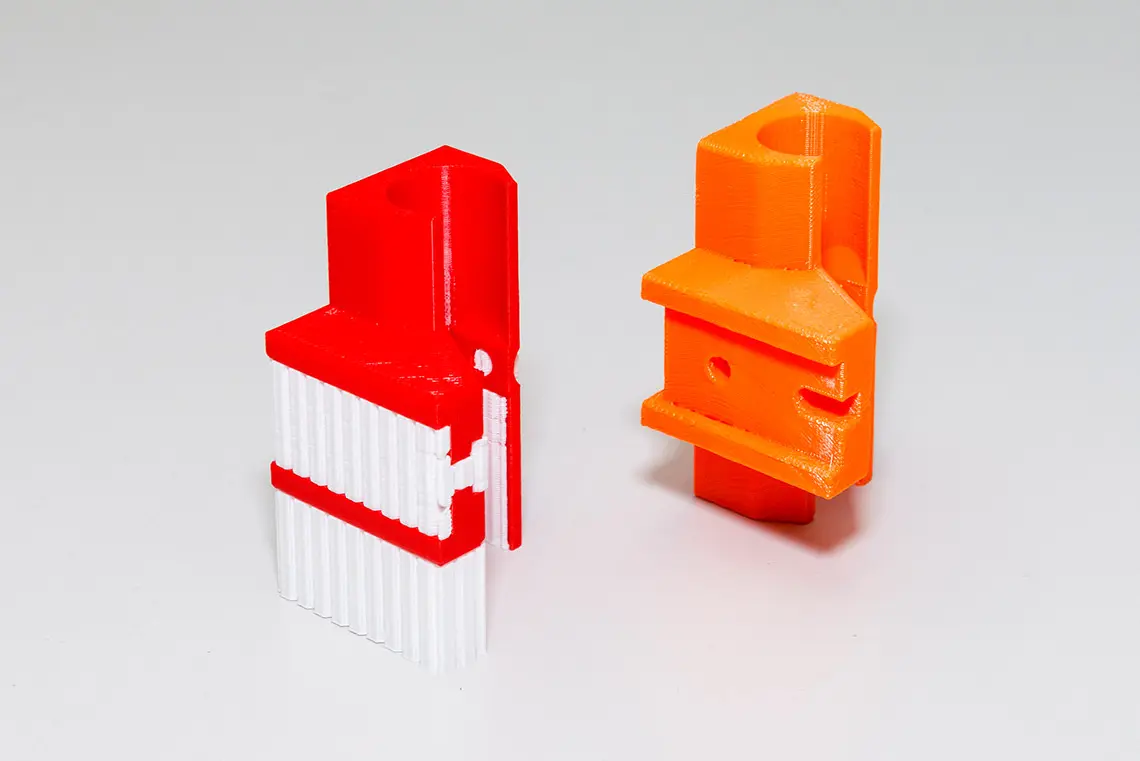

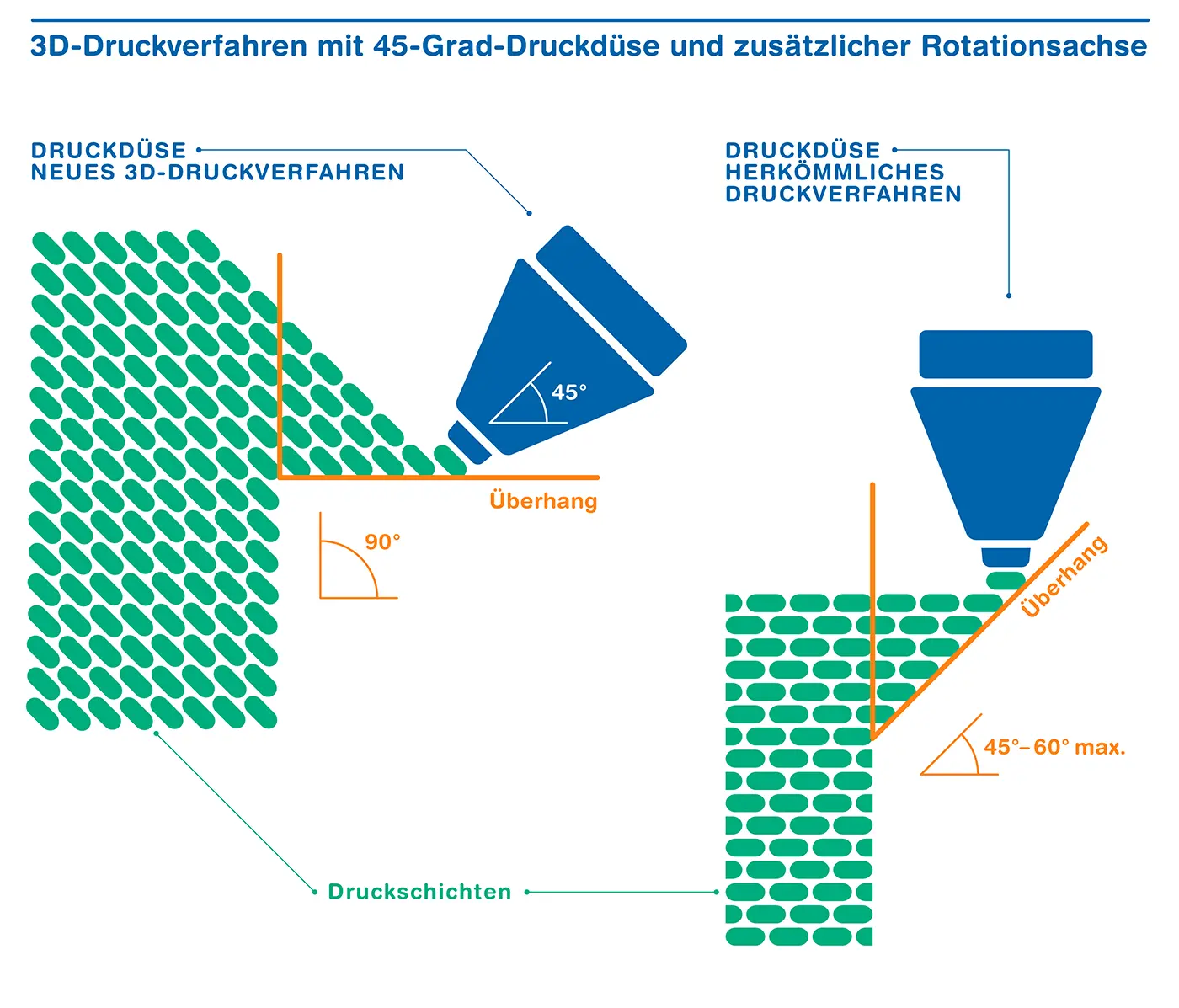

3D printers are enjoying ever greater popularity. In the fused filament fabrication process, which is already widely used, a thermoplastic is applied layer by layer until the desired component has been produced. However, if an overhanging shape is to be printed, then, from a certain angle, conventional 3D printers have to use support material. These printed support structures must then be removed from the actual object in an additional step. Traces frequently remain visible.

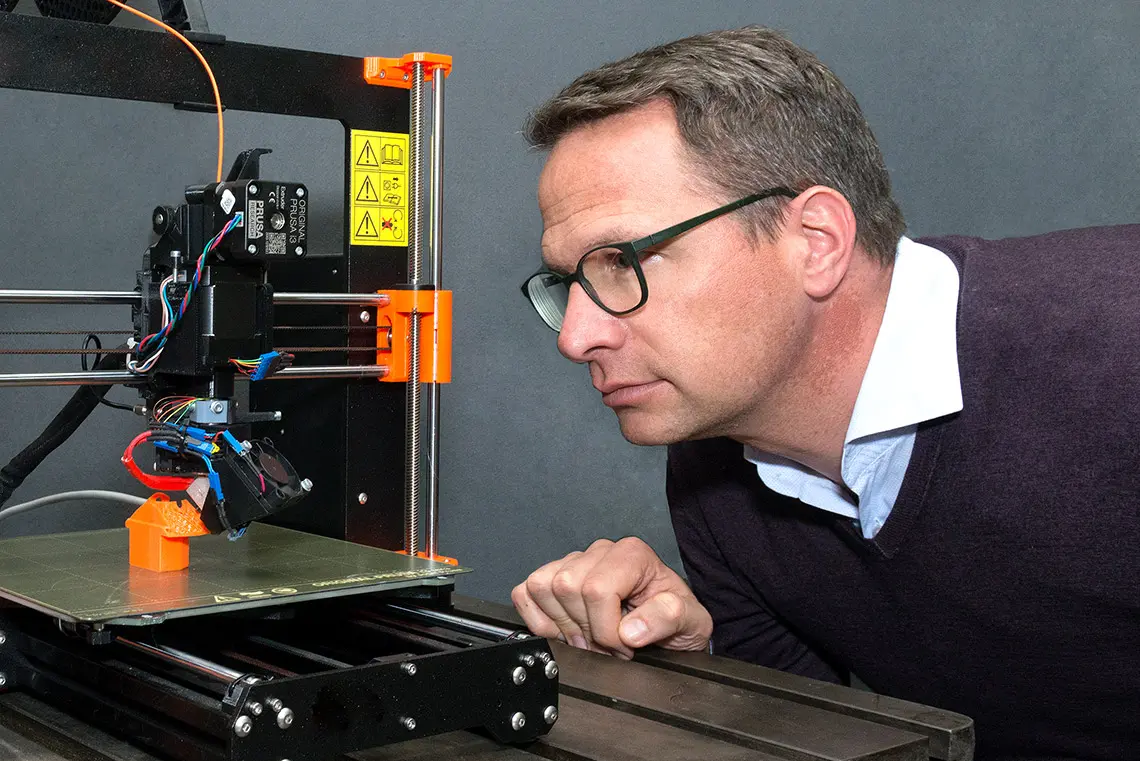

Two ZHAW researchers have now found a remedy to this problem. Their solution is to tilt the printhead nozzle by 45 degrees and to integrate an additional rotation axis. This means that the printhead can now rotate around its own axis as desired. “Our ‘RotBot’ 3D printer is able to print any structure without support material,” says Wilfried J. Elspass, Head of Systems Engineering research at the ZHAW Institute of Mechatronic Systems. “This means first of all that we need less material, and secondly, that printing times are shorter. Thirdly, post-processing – that is, the removal of support material – is completely eliminated.”

Print data is transformed twice

Together with the ZHAW Institute of Applied Mathematics and Physics, the researchers were able to develop a special print-data preparation method so as to be able to print using their new process at all. “It is not based on parallel layers to the print bed, as is usually the case, but rather on cone-shaped ones,” explains ZHAW researcher Michael Wüthrich. The researchers have designed two new algorithms to this end. A first algorithm transforms the geometric data so that the operating commands for the printer can be generated using conventional software. A second algorithm then has to transform these operating commands back again so that the part is finally printed on the RotBot according to the initial geometry. “The time-consuming part of the data preparation is thus still handled using commercially available software and the geometries can be printed fully automatically,” says Wüthrich.

Marketable as an upgrade kit

A 3D printer which was able to print overhangs without support material thanks to its six axes and moveable printing plate had already been presented by the ZHAW School of Engineering as far back as four years ago. The creation of the print data was, however, time-consuming as it required coordination between the printhead, the printing plate and the printed part. In contrast to the prototype presented at that time, the technology used in the RotBot is simpler. “RotBot can be built relatively easily on the basis of a conventional printer with Cartesian kinematics,” says Wilfried J. Elspass. The ZHAW researchers in Winterthur say that certain manufacturers could soon be offering their solution as an upgrade kit for their 3D printers.

Downloads and Links

- Press release «Upgrade for 3D printer saves time and support material» (PDF 196 kB)

- Publication «Novel 4-Axis 3D Printing Process to Print Overhangs Without Support Material»

- Picutre 1 (JPG 2.76 MB)

- Picutre 2 (JPG 3.13 MB)

- Picutre 3 (JPG 3.94 MB)

- Picutre 4 (JPG 3.51 MB)

- Picutre 5 (JPG 4.70 MB)

- Picutre 6 (JPG 3.48 MB)

- Picutre 7 (JPG 5.72 MB)

Contact

Prof. Wilfried J. Elspass, Institute of Mechatronic Systems, ZHAW School of Engineering, phone 058 934 78 28, e-mail wilfried.elspass@zhaw.ch

Michael Wüthrich, Institute of Mechatronic Systems, ZHAW School of Engineering, phone 058 934 78 25, e-mail michael.wuethrich@zhaw.ch

Matthias Kleefoot, Public Relations, ZHAW School of Engineering, phone 058 934 70 85, e-mail medien.engineering@zhaw.ch