For rapid descents: ZHAW researchers develop high-tech ski wax

ZHAW researchers have developed a new type of ski wax that sticks longer thanks to a designer molecule. In laboratory tests, the coating proved to be twice as durable as conventional ski wax. Field tests on the slopes promise new record times.

The more water-repellent the ski base is, the faster the ski becomes. This is because friction creates a thin film of water that serves as a lubricant, so to speak. Today, for example, more effective highly fluorinated carbon compounds are used instead of simple paraffin waxes. However, what all previous high-performance ski waxes have in common is that they wear off quickly. This means that the running surfaces are bare again after a short time and friction is increased. "Conventional ski waxes don't even last for the duration of a race," says Konstantin Siegmann, project manager at the ZHAW School of Engineering. "That's because ski bases are made of an extremely low-reaction plastic that hardly forms any chemical bonds."

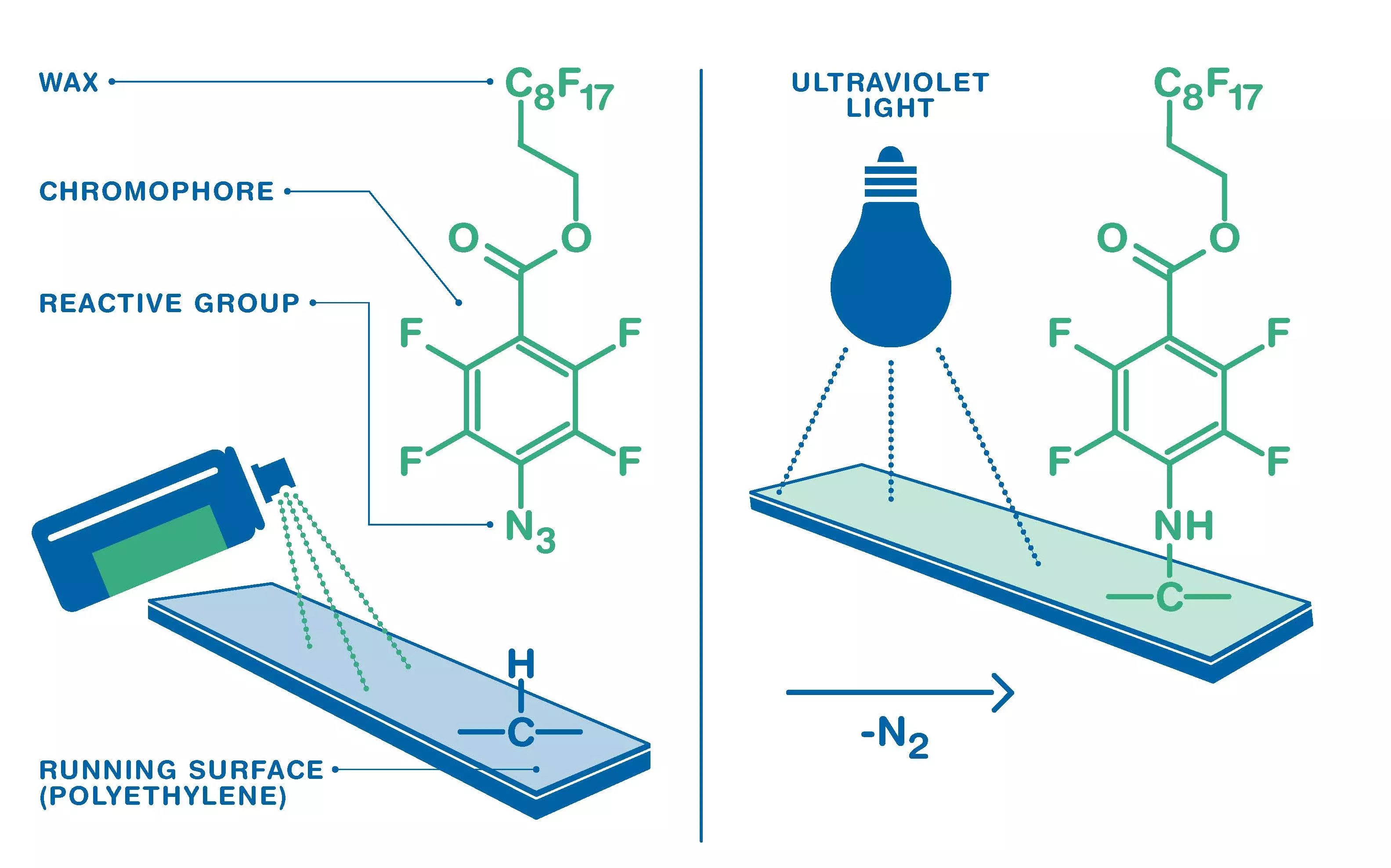

Designer molecule forms chemical bond

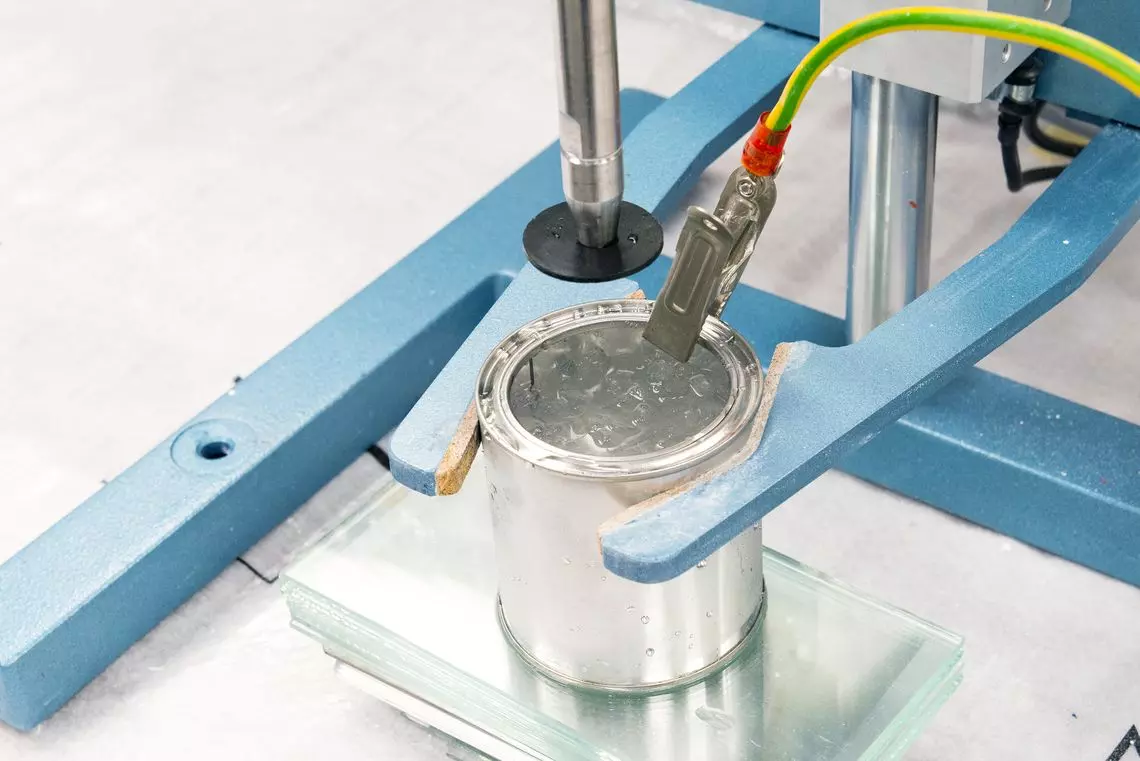

Sponsored by Innosuisse, researchers from the Institute of Materials and Process Engineering at the ZHAW, in association with the TOKO company, developed a wax to solve this problem by building a new designer molecule through a chemical reaction. If this synthetic molecule is irradiated by a mercury-vapour lamp, the wax forms a tight bond with the ski surface and thus remains in place for longer. The molecule reacts with UV light and splits of nitrogen, leaving a highly reactive nitrene, which binds the wax to the low-reactive plastic.

Performance improves up to 1.5 per cent

Abrasion tests performed in the laboratory by ZHAW researchers proved that this photoreactive ski wax is indeed more durable than conventional wax. “The photoreactive ski wax proved to rub off twice as slowly as conventional high-performance ski wax,” according to Siegmann. The laboratory tests were followed by extensive field tests with ski specialists. The focus was on cross-country skiing because the boundary conditions could be monitored better. In cold weather conditions, the photoreactive ski wax showed the least friction. The time gain amounted to a saving of between 0.1 and 0.3 seconds in 20-second downhill runs, as compared with conventional high-performance ski wax. This equals an improvement in performance of up to 1.5 per cent. “This exceeded the improvement we had hoped for by far. The test runners didn't want to give back the photoreactive ski wax,” says Siegmann.

ZHAW ski wax to be used at the Olympics

Soon, these successful test runs could be reflected in new best times at tournaments. The ZHAW's photoreactive ski wax will be used at the Winter Olympics in South Korea in February. Amateur skiers, however, will have to be patient.

“At present, applying the wax using mercury-vapour lamps is still too expensive,” Siegmann states. “As soon as the wax can be applied more economically, it will also be accessible to amateurs."

Downloads and further information

Peer-Reviewed-Artikel

- Photografting of Perfluoroalkanes onto Polyethylene Surfaces via Azide/Nitrene Chemistry. Siegmann, K.; Inauen, J.; Villamaina, D.; Winkler, M. J. Appl. Surf. Sci. 2017, 396, 672-680.

http://dx.doi.org/10.1016/j.apsusc.2016.11.007 - Spectroscopy on photografted polyethylene surfaces using a perfluorophenyl azide: Evidence for covalent attachment. Siegmann, K.; Inauen, J.; Sterchi, R.; Winkler, M. Surf Interface Anal. 2018, 50, 205-211.

https://doi.org/10.1002/sia.6359

Contacts

Dr. Konstantin Siegmann, Institute of Materials and Process Engineering, ZHAW School of Engineering, phone: 058 934 69 29, e-mail: konstantin.siegmann@zhaw.ch

Matthias Kleefoot, Public Relations, ZHAW School of Engineering, phone: 058 934 70 85, e-mail: medien.engineering@zhaw.ch