Electric cylinders for Industry 4.0

Although ZHAW graduate Jeremias Wehrli only came up with the idea for his start-up after graduating, there is still a great deal of know-how from the university that has gone into "Cyltronic". The young entrepreneur wants to replace conventional pneumatic cylinders, as they are found in industrial plants around the world, with innovative electric cylinders.

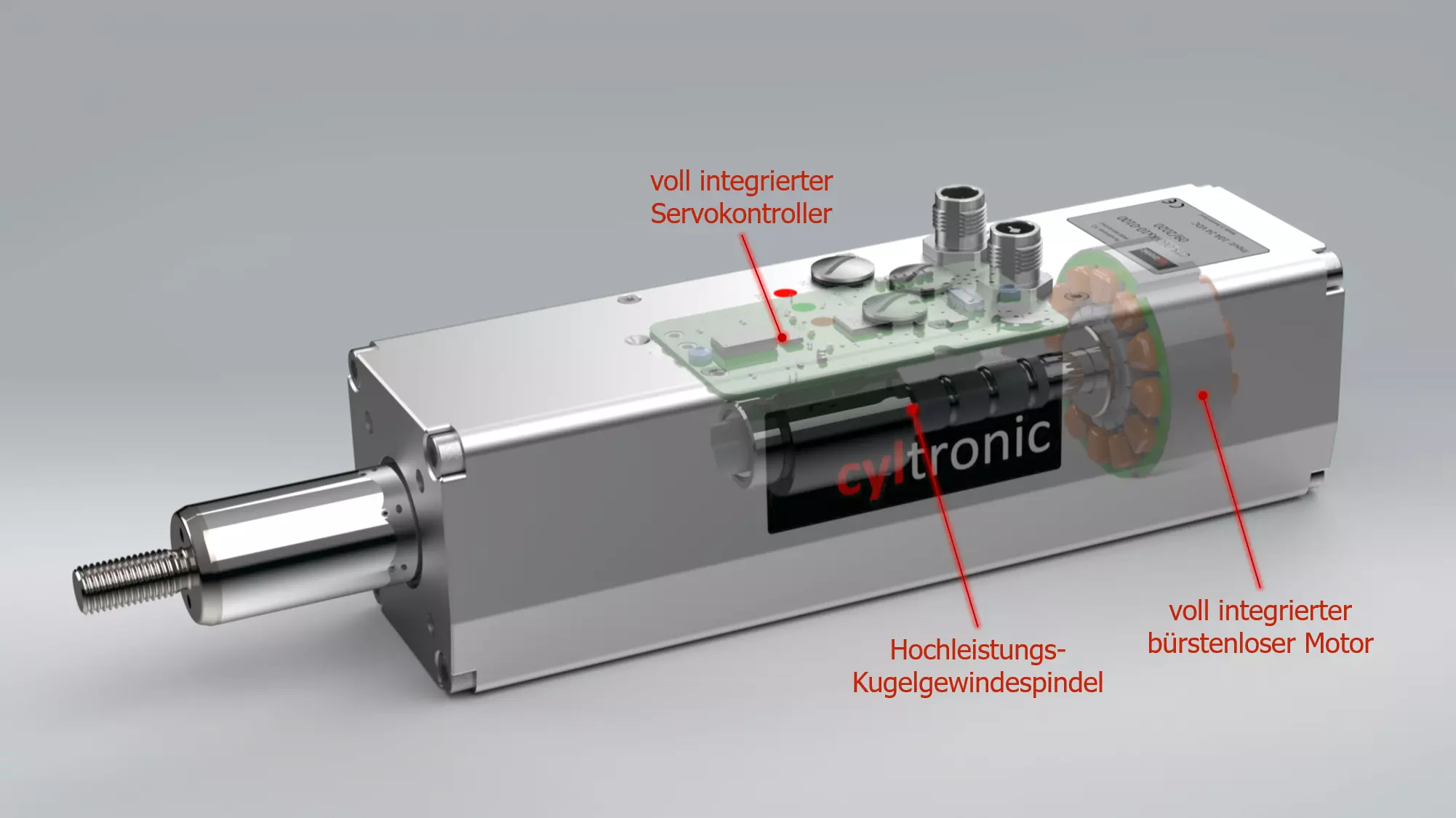

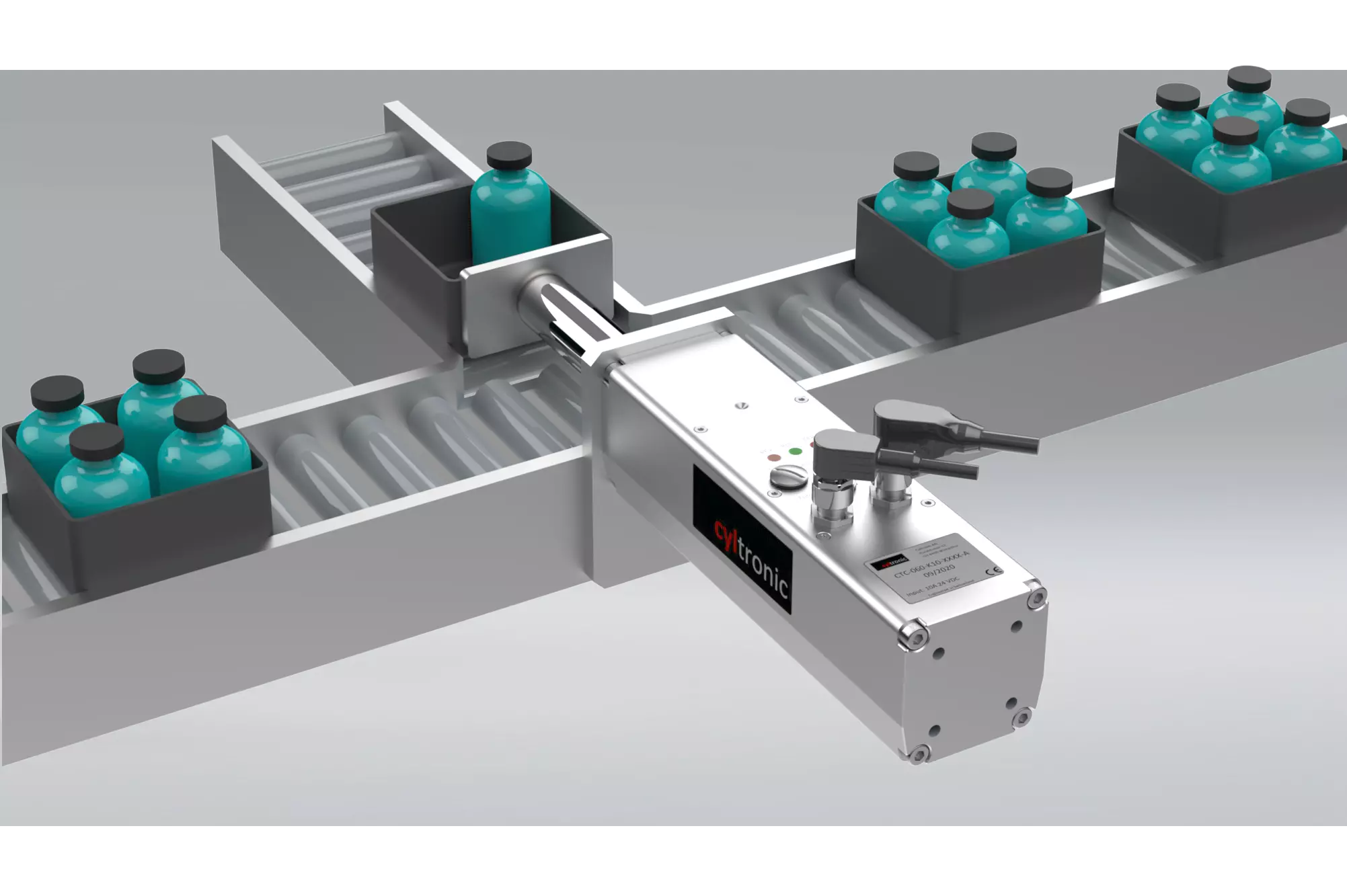

After completing his Bachelor’s degree in Mechanical Engineering at the ZHAW School of Engineering, Jeremias Wehrli went on to work for various companies as an external development engineer. While working at a business in the food industry, he noticed a packaging system, or more precisely the hissing of the pneumatics. “I could literally hear the inefficiency of the system,” says Jeremias Wehrli. He still remembers how compressed air was being lost due to leakage, meaning that the already energy-intensive technology was consuming even more resources than necessary. Just a few years after this pivotal moment, the ZHAW graduate now finds himself as a start-up founder. With his company Cyltronic, he markets an energy-efficient alternative to traditional pneumatic cylinders. “Electric cylinders with a mechanical spindle inside are nothing new,” explains Wehrli. “With us, however, all of the electronics are compactly installed within the cylinder.” His product has the same installation length as standard pneumatic cylinders and can be used to replace them with little effort. Additional parts for the control electronics or similar components are not required.

“It makes sense to use our component straight away instead of transferring traditional compressed air technology into the digital world.”

Jeremias Wehrli, ZHAW graduate and start-up founder

Efficient, precise and digital

The road from his initial idea to the production of a marketable product led the ZHAW graduate back to his place of study. Together with the Institute of Mechatronic Systems (IMS), he had initially advertised a project thesis and a Bachelor’s thesis. “Thanks to the work completed by the students, we gained a concrete market analysis and a functional model as a basis for our development,” says Wehrli. Today, he continues to work with the IMS to further improve the product. “We want to optimise the controller while still keeping the software as simple as possible,” explains Wehrli. He points out that although the compact design in the smallest of spaces within the cylinder housing is the biggest challenge, it also represents a unique selling point. In addition to the high level of energy efficiency, the positioning, which is accurate to a tenth of a millimetre, is a further factor that speaks in favour of the electric cylinder. “It is almost impossible to achieve the precision of a mechanical spindle with compressed air. And even if this is possible, it is complex and costly,” continues Wehrli. He sees a further major benefit of his product in the transformation to Industry 4.0: “It makes sense to use our component straight away instead of transferring traditional compressed air technology into the digital world.”

100 cylinders as part of a funding project

Cyltronic currently finds itself in the pilot phase, explains Wehrli: “The first companies are now retrofitting certain systems with our solution.” The main priority is to build up references, which is why Wehrli wants to replace 100 cylinders over the coming months. His project is even being funded by the Swiss Federal Office of Energy. “In this way, the federal government will be able to gather experience with respect to how much energy can actually be saved. The fact is that we save resources with every movement. The more the cylinders are in motion, the more apparent the difference in energy consumption becomes,” says Wehrli, who has been fully involved in his start-up since summer 2020. And the more cylinders the ZHAW graduate replaces, the fewer packaging systems that will hiss in future.

More on the start-up: www.cyltronic.ch