Powder Coating: Simulation-Based Prototype Development of Novel Powder Coating Nozzles

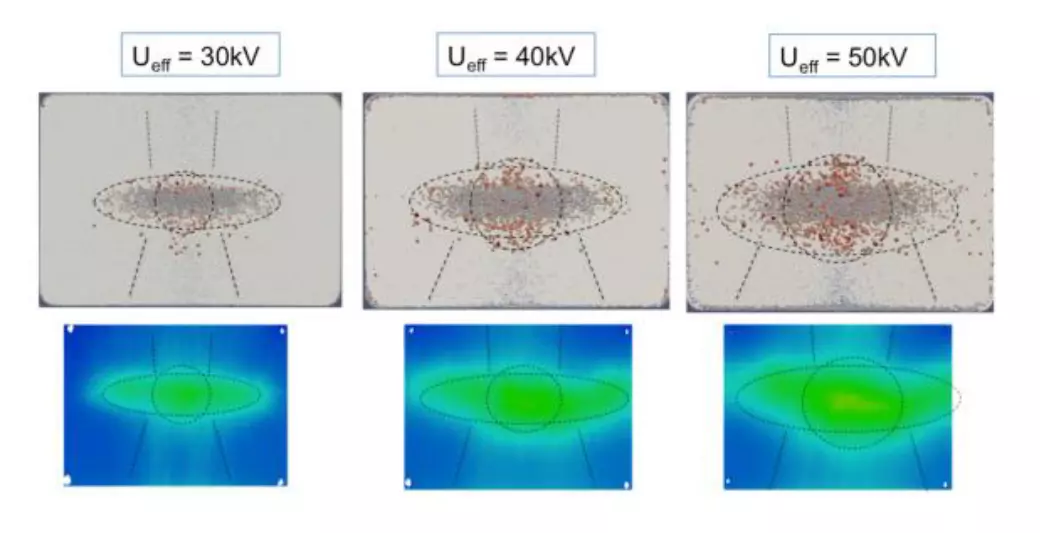

profile substrate. Example for qualitative correspondence of simu-

lated (top) and measured (bottom) coating patterns. Here the front

side of an A4-plate substrate was coated at a pistol-substrate-dis-

tance D=20cm, while applying an airflow rate Q=3m3/h and effective

voltages Ueff of 30kV, 40kV and 50kV respectively. It can be seen

that the main qualitative coating-pattern-features, as well as trends

of simulations and experiments match well.

Through the development of an extensive numerical Euler-Lagrangian simulation model, highly efficient nozzle geometries were developed. The simulations were validated on measurement series covering several thousand experiments. The new nozzles which resulted from the project achieved an increase in coating efficiency by over 15%.

In the course of this project, an extensive numerical Euler-Lagrangian simulation model for powder coating applications was developed and comprehensively validated. The model couples all relevant physical influencing factors such as electrostatic field strength, air flow, particle size distribution, particle-substrate interaction, particle-particle interaction and gravitation. The solver was validated by several thousand coating experiments and their evaluation. With this new numerical model, a powder coating process can now be quantified in a previously unattainable quality, both quantitatively and qualitatively. This new numerical analysis method has already provided far-reaching insights into the interrelationships between process parameters and coating results.

Based on these simulation results and extensive measurements, it was possible to design a set of new internal geometries for the nozzle part of the pistol. These new nozzle types, while in a prototype stage, showed the potential to increase process metrics such as homogeneity and coating efficiency. From the set of suggested new geometry types, two were selected by the customer for further investigation.

Both selected types showed an increase in the coating efficiency by over 15% for the complete parameter range. Through further investigation and development of the selected nozzles, the design was improved to achieve a coating efficiency increase of 23-31% for the most commonly used parameter ranges.